Page 130 - Trenchless Technology Piping Installation and Inspection

P. 130

96 Cha pte r T h ree

Non-structural Semi-structural Structural

System Class Class I Class II Class III Class IV

Corrosion Yes Yes Yes Yes

protection

Gap spanning No Yes Yes Yes

capability

Inherent ring No (Depends No (Depends Yes Yes

stiffness on bonding) on bonding) (Self support) (Self support)

Survives No No No Yes

burst failure of

existing pipe

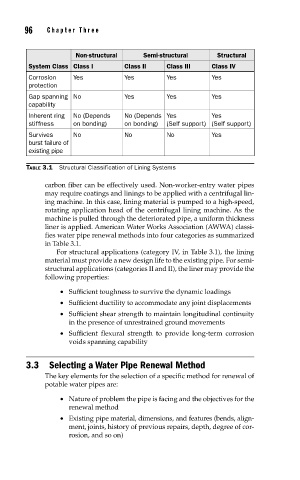

TABLE 3.1 Structural Classification of Lining Systems

carbon fiber can be effectively used. Non-worker-entry water pipes

may require coatings and linings to be applied with a centrifugal lin-

ing machine. In this case, lining material is pumped to a high-speed,

rotating application head of the centrifugal lining machine. As the

machine is pulled through the deteriorated pipe, a uniform thickness

liner is applied. American Water Works Association (AWWA) classi-

fies water pipe renewal methods into four categories as summarized

in Table 3.1.

For structural applications (category IV, in Table 3.1), the lining

material must provide a new design life to the existing pipe. For semi-

structural applications (categories II and II), the liner may provide the

following properties:

• Sufficient toughness to survive the dynamic loadings

• Sufficient ductility to accommodate any joint displacements

• Sufficient shear strength to maintain longitudinal continuity

in the presence of unrestrained ground movements

• Sufficient flexural strength to provide long-term corrosion

voids spanning capability

3.3 Selecting a Water Pipe Renewal Method

The key elements for the selection of a specific method for renewal of

potable water pipes are:

• Nature of problem the pipe is facing and the objectives for the

renewal method

• Existing pipe material, dimensions, and features (bends, align-

ment, joints, history of previous repairs, depth, degree of cor-

rosion, and so on)