Page 149 - Trenchless Technology Piping Installation and Inspection

P. 149

Coatings and Linings for Potable W ater Pipe Distributions 115

Lining rig

Rack-feed boring Air

machine compressor

Umbilical

hose drum

Lined pipe

Cleaning Static mixer section

head

Corrosion/

encrustation

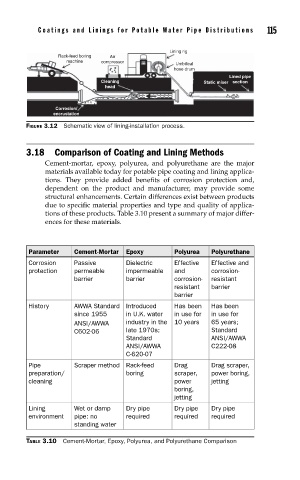

FIGURE 3.12 Schematic view of lining-installation process.

3.18 Comparison of Coating and Lining Methods

Cement-mortar, epoxy, polyurea, and polyurethane are the major

materials available today for potable pipe coating and lining applica-

tions. They provide added benefits of corrosion protection and,

dependent on the product and manufacturer, may provide some

structural enhancements. Certain differences exist between products

due to specific material properties and type and quality of applica-

tions of these products. Table 3.10 present a summary of major differ-

ences for these materials.

Parameter Cement-Mortar Epoxy Polyurea Polyurethane

Corrosion Passive Dielectric Effective Effective and

protection permeable impermeable and corrosion-

barrier barrier corrosion- resistant

resistant barrier

barrier

History AWWA Standard Introduced Has been Has been

since 1955 in U.K. water in use for in use for

ANSI/AWWA industry in the 10 years 65 years;

C602-06 late 1970s; Standard

Standard ANSI/AWWA

ANSI/AWWA C222-08

C-620-07

Pipe Scraper method Rack-feed Drag Drag scraper,

preparation/ boring scraper, power boring,

cleaning power jetting

boring,

jetting

Lining Wet or damp Dry pipe Dry pipe Dry pipe

environment pipe: no required required required

standing water

TABLE 3.10 Cement-Mortar, Epoxy, Polyurea, and Polyurethane Comparison