Page 220 - Trenchless Technology Piping Installation and Inspection

P. 220

184 Cha pte r F i v e

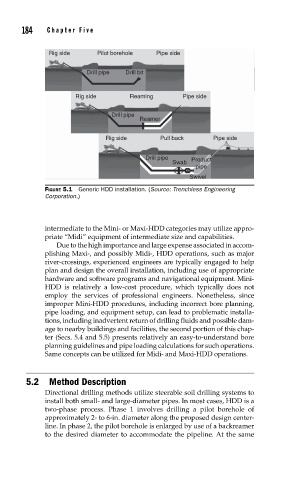

Rig side Pilot borehole Pipe side

Drill pipe Drill bit

Rig side Reaming Pipe side

Drill pipe

Reamer

Rig side Pull back Pipe side

Drill pipe Product

Swab

pipe

Swivel

FIGURE 5.1 Generic HDD installation. (Source: Trenchless Engineering

Corporation.)

intermediate to the Mini- or Maxi-HDD categories may utilize appro-

priate “Midi” equipment of intermediate size and capabilities.

Due to the high importance and large expense associated in accom-

plishing Maxi-, and possibly Midi-, HDD operations, such as major

river-crossings, experienced engineers are typically engaged to help

plan and design the overall installation, including use of appropriate

hardware and software programs and navigational equipment. Mini-

HDD is relatively a low-cost procedure, which typically does not

employ the services of professional engineers. Nonetheless, since

improper Mini-HDD procedures, including incorrect bore planning,

pipe loading, and equipment setup, can lead to problematic installa-

tions, including inadvertent return of drilling fluids and possible dam-

age to nearby buildings and facilities, the second portion of this chap-

ter (Secs. 5.4 and 5.5) presents relatively an easy-to-understand bore

planning guidelines and pipe loading calculations for such operations.

Same concepts can be utilized for Midi- and Maxi-HDD operations.

5.2 Method Description

Directional drilling methods utilize steerable soil drilling systems to

install both small- and large-diameter pipes. In most cases, HDD is a

two-phase process. Phase 1 involves drilling a pilot borehole of

approximately 2- to 6-in. diameter along the proposed design center-

line. In phase 2, the pilot borehole is enlarged by use of a backreamer

to the desired diameter to accommodate the pipeline. At the same