Page 221 - Trenchless Technology Piping Installation and Inspection

P. 221

Pr oject Considerations for Horizontal Dir ectional Drilling 185

time, the product pipe is connected to the end of the drilling rod by a

swivel and pulled back through the enlarged pilot borehole. How-

ever, for large-diameter pipes, a separate (intermediate) phase

comprising several passes of backreaming (or “prereaming”) may be

necessary to enlarge the borehole to the desired size. In this case, the

pullback operation is performed simultaneously with the final back-

reaming operation. The pilot borehole is drilled with a surface-

launched rig with an inclined carriage, typically adjusted at an angle

of 8° to 20° with the ground surface. Figure 5.1 illustrates a generic

HDD installation.

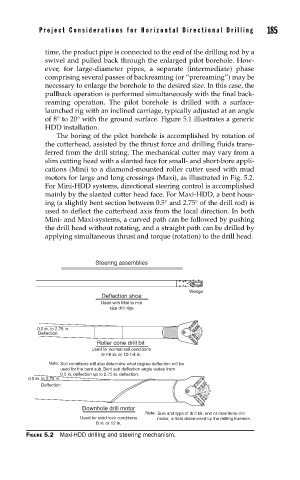

The boring of the pilot borehole is accomplished by rotation of

the cutterhead, assisted by the thrust force and drilling fluids trans-

ferred from the drill string. The mechanical cutter may vary from a

slim cutting head with a slanted face for small- and short-bore appli-

cations (Mini) to a diamond-mounted roller cutter used with mud

motors for large and long crossings (Maxi), as illustrated in Fig. 5.2.

For Mini-HDD systems, directional steering control is accomplished

mainly by the slanted cutter head face. For Maxi-HDD, a bent hous-

ing (a slightly bent section between 0.5° and 2.75° of the drill rod) is

used to deflect the cutterhead axis from the local direction. In both

Mini- and Maxi-systems, a curved path can be followed by pushing

the drill head without rotating, and a straight path can be drilled by

applying simultaneous thrust and torque (rotation) to the drill head.

Steering assemblies

Wedge

Deflection shoe

Used with Mini to mid

size drill rigs

0.5 in. to 2.75 in.

Deflection

Roller cone drill bit

Used for normal soil conditions

9-7/8 in. or 12-1/4 in.

Note: Soil conditions will also determine what degree deflection will be

used for the bent sub. Bent sub deflection angle varies from

0.5 in. deflection up to 2.75 in. deflection.

0.5 in. to 2.75 in.

Deflection

Downhole drill motor

Note: Size and type of drill bit, and or downhole drill

Used for solid rock conditions motor, is field determined by the drilling foreman.

B in. or 12 in.

FIGURE 5.2 Maxi-HDD drilling and steering mechanism.