Page 242 - Trenchless Technology Piping Installation and Inspection

P. 242

206 Cha pte r F i v e

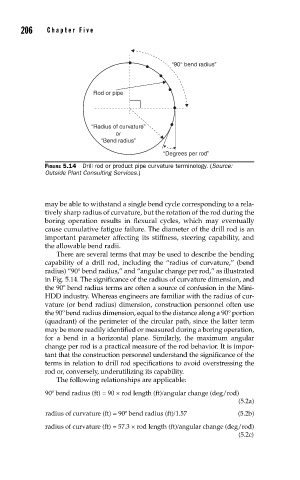

“90° bend radius”

Rod or pipe

“Radius of curvature”

or

“Bend radius”

“Degrees per rod”

FIGURE 5.14 Drill rod or product pipe curvature terminology. (Source:

Outside Plant Consulting Services.)

may be able to withstand a single bend cycle corresponding to a rela-

tively sharp radius of curvature, but the rotation of the rod during the

boring operation results in flexural cycles, which may eventually

cause cumulative fatigue failure. The diameter of the drill rod is an

important parameter affecting its stiffness, steering capability, and

the allowable bend radii.

There are several terms that may be used to describe the bending

capability of a drill rod, including the “radius of curvature,” (bend

radius) “90° bend radius,” and “angular change per rod,” as illustrated

in Fig. 5.14. The significance of the radius of curvature dimension, and

the 90º bend radius terms are often a source of confusion in the Mini-

HDD industry. Whereas engineers are familiar with the radius of cur-

vature (or bend radius) dimension, construction personnel often use

the 90º bend radius dimension, equal to the distance along a 90° portion

(quadrant) of the perimeter of the circular path, since the latter term

may be more readily identified or measured during a boring operation,

for a bend in a horizontal plane. Similarly, the maximum angular

change per rod is a practical measure of the rod behavior. It is impor-

tant that the construction personnel understand the significance of the

terms in relation to drill rod specifications to avoid overstressing the

rod or, conversely, underutilizing its capability.

The following relationships are applicable:

90º bend radius (ft) = 90 × rod length (ft)/angular change (deg/rod)

(5.2a)

radius of curvature (ft) = 90º bend radius (ft)/1.57 (5.2b)

radius of curvature (ft) = 57.3 × rod length (ft)/angular change (deg/rod)

(5.2c)