Page 268 - Trenchless Technology Piping Installation and Inspection

P. 268

232 Cha pte r S i x

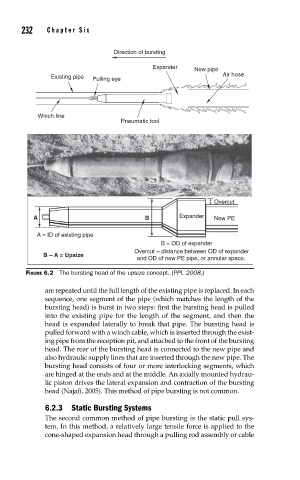

Direction of bursting

Expander New pipe

Air hose

Existing pipe

Pulling eye

Winch line

Pneumatic tool

Overcut

A B Expander New PE

A = ID of existing pipe

B = OD of expander

Overcut = distance between OD of expander

B – A = Upsize

and OD of new PE pipe, or annular space.

FIGURE 6.2 The bursting head of the upsize concept. (PPI, 2008.)

are repeated until the full length of the existing pipe is replaced. In each

sequence, one segment of the pipe (which matches the length of the

bursting head) is burst in two steps: first the bursting head is pulled

into the existing pipe for the length of the segment, and then the

head is expanded laterally to break that pipe. The bursting head is

pulled forward with a winch cable, which is inserted through the exist-

ing pipe from the reception pit, and attached to the front of the bursting

head. The rear of the bursting head is connected to the new pipe and

also hydraulic supply lines that are inserted through the new pipe. The

bursting head consists of four or more interlocking segments, which

are hinged at the ends and at the middle. An axially mounted hydrau-

lic piston drives the lateral expansion and contraction of the bursting

head (Najafi, 2005). This method of pipe bursting is not common.

6.2.3 Static Bursting Systems

The second common method of pipe bursting is the static pull sys-

tem. In this method, a relatively large tensile force is applied to the

cone-shaped expansion head through a pulling rod assembly or cable