Page 272 - Trenchless Technology Piping Installation and Inspection

P. 272

236 Cha pte r S i x

Direction of insertion

Lubricant system Power unit

Tenbusch

Surface improvements

Work pit

9' × 9' New pipe

Back Cracker Ex.

stop MH

Front jack Lead

Pipe Cone Existing

adapter expander pipe

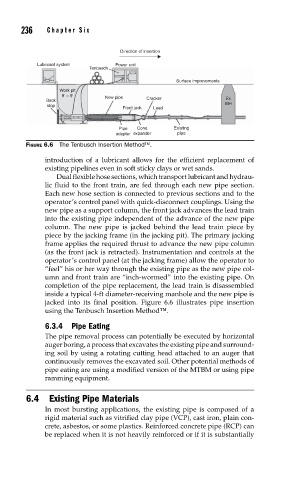

FIGURE 6.6 The Tenbusch Insertion Method™.

introduction of a lubricant allows for the efficient replacement of

existing pipelines even in soft sticky clays or wet sands.

Dual flexible hose sections, which transport lubricant and hydrau-

lic fluid to the front train, are fed through each new pipe section.

Each new hose section is connected to previous sections and to the

operator’s control panel with quick-disconnect couplings. Using the

new pipe as a support column, the front jack advances the lead train

into the existing pipe independent of the advance of the new pipe

column. The new pipe is jacked behind the lead train piece by

piece by the jacking frame (in the jacking pit). The primary jacking

frame applies the required thrust to advance the new pipe column

(as the front jack is retracted). Instrumentation and controls at the

operator’s control panel (at the jacking frame) allow the operator to

“feel” his or her way through the existing pipe as the new pipe col-

umn and front train are “inch-wormed” into the existing pipe. On

completion of the pipe replacement, the lead train is disassembled

inside a typical 4-ft diameter-receiving manhole and the new pipe is

jacked into its final position. Figure 6.6 illustrates pipe insertion

using the Tenbusch Insertion Method™.

6.3.4 Pipe Eating

The pipe removal process can potentially be executed by horizontal

auger boring, a process that excavates the existing pipe and surround-

ing soil by using a rotating cutting head attached to an auger that

continuously removes the excavated soil. Other potential methods of

pipe eating are using a modified version of the MTBM or using pipe

ramming equipment.

6.4 Existing Pipe Materials

In most bursting applications, the existing pipe is composed of a

rigid material such as vitrified clay pipe (VCP), cast iron, plain con-

crete, asbestos, or some plastics. Reinforced concrete pipe (RCP) can

be replaced when it is not heavily reinforced or if it is substantially