Page 276 - Trenchless Technology Piping Installation and Inspection

P. 276

240 Cha pte r S i x

environmental intrusion. Pipe bursting creates minimal interfer-

ence with other utilities and less safety hazards (for both operators

and the public) due to reduced open excavation.

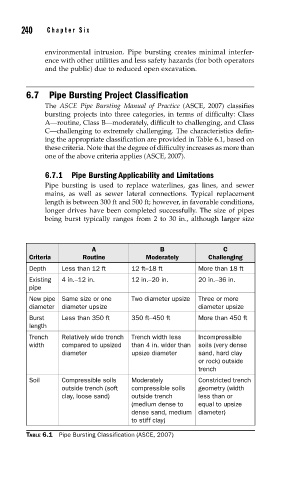

6.7 Pipe Bursting Project Classification

The ASCE Pipe Bursting Manual of Practice (ASCE, 2007) classifies

bursting projects into three categories, in terms of difficulty: Class

A—routine, Class B—moderately, difficult to challenging, and Class

C—challenging to extremely challenging. The characteristics defin-

ing the appropriate classification are provided in Table 6.1, based on

these criteria. Note that the degree of difficulty increases as more than

one of the above criteria applies (ASCE, 2007).

6.7.1 Pipe Bursting Applicability and Limitations

Pipe bursting is used to replace waterlines, gas lines, and sewer

mains, as well as sewer lateral connections. Typical replacement

length is between 300 ft and 500 ft; however, in favorable conditions,

longer drives have been completed successfully. The size of pipes

being burst typically ranges from 2 to 30 in., although larger size

A B C

Criteria Routine Moderately Challenging

Depth Less than 12 ft 12 ft–18 ft More than 18 ft

Existing 4 in.–12 in. 12 in.–20 in. 20 in.–36 in.

pipe

New pipe Same size or one Two diameter upsize Three or more

diameter diameter upsize diameter upsize

Burst Less than 350 ft 350 ft–450 ft More than 450 ft

length

Trench Relatively wide trench Trench width less Incompressible

width compared to upsized than 4 in. wider than soils (very dense

diameter upsize diameter sand, hard clay

or rock) outside

trench

Soil Compressible soils Moderately Constricted trench

outside trench (soft compressible soils geometry (width

clay, loose sand) outside trench less than or

(medium dense to equal to upsize

dense sand, medium diameter)

to stiff clay)

TABLE 6.1 Pipe Bursting Classification (ASCE, 2007)