Page 280 - Trenchless Technology Piping Installation and Inspection

P. 280

244 Cha pte r S i x

instructed to take the necessary measures to handle and dispose of

this contaminated soil.

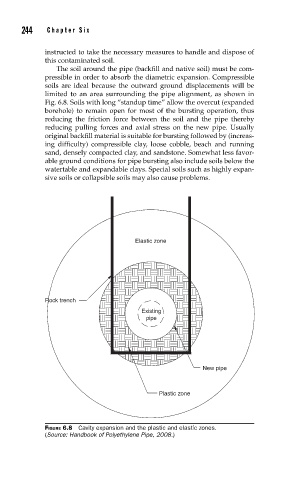

The soil around the pipe (backfill and native soil) must be com-

pressible in order to absorb the diametric expansion. Compressible

soils are ideal because the outward ground displacements will be

limited to an area surrounding the pipe alignment, as shown in

Fig. 6.8. Soils with long “standup time” allow the overcut (expanded

borehole) to remain open for most of the bursting operation, thus

reducing the friction force between the soil and the pipe thereby

reducing pulling forces and axial stress on the new pipe. Usually

original backfill material is suitable for bursting followed by (increas-

ing difficulty) compressible clay, loose cobble, beach and running

sand, densely compacted clay, and sandstone. Somewhat less favor-

able ground conditions for pipe bursting also include soils below the

watertable and expandable clays. Special soils such as highly expan-

sive soils or collapsible soils may also cause problems.

Elastic zone

Rock trench

Existing

pipe

New pipe

Plastic zone

FIGURE 6.8 Cavity expansion and the plastic and elastic zones.

(Source: Handbook of Polyethylene Pipe, 2008.)