Page 290 - Trenchless Technology Piping Installation and Inspection

P. 290

254 Cha pte r S i x

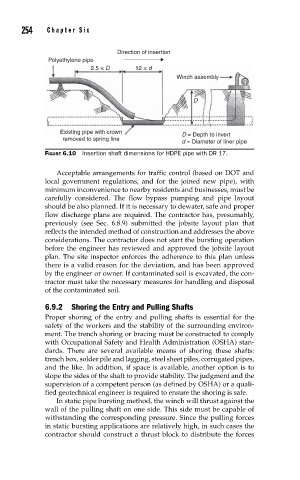

Direction of insertion

Polyethylene pipe

2.5 × D 12 × d

Winch assembly

D

Existing pipe with crown D = Depth to invert

removed to spring line

d = Diameter of liner pipe

FIGURE 6.10 Insertion shaft dimensions for HDPE pipe with DR 17.

Acceptable arrangements for traffic control (based on DOT and

local government regulations, and for the joined new pipe), with

minimum inconvenience to nearby residents and businesses, must be

carefully considered. The flow bypass pumping and pipe layout

should be also planned. If it is necessary to dewater, safe and proper

flow discharge plans are required. The contractor has, presumably,

previously (see Sec. 6.8.9) submitted the jobsite layout plan that

reflects the intended method of construction and addresses the above

considerations. The contractor does not start the bursting operation

before the engineer has reviewed and approved the jobsite layout

plan. The site inspector enforces the adherence to this plan unless

there is a valid reason for the deviation, and has been approved

by the engineer or owner. If contaminated soil is excavated, the con-

tractor must take the necessary measures for handling and disposal

of the contaminated soil.

6.9.2 Shoring the Entry and Pulling Shafts

Proper shoring of the entry and pulling shafts is essential for the

safety of the workers and the stability of the surrounding environ-

ment. The trench shoring or bracing must be constructed to comply

with Occupational Safety and Health Administration (OSHA) stan-

dards. There are several available means of shoring these shafts:

trench box, solder pile and lagging, steel sheet piles, corrugated pipes,

and the like. In addition, if space is available, another option is to

slope the sides of the shaft to provide stability. The judgment and the

supervision of a competent person (as defined by OSHA) or a quali-

fied geotechnical engineer is required to ensure the shoring is safe.

In static pipe bursting method, the winch will thrust against the

wall of the pulling shaft on one side. This side must be capable of

withstanding the corresponding pressure. Since the pulling forces

in static bursting applications are relatively high, in such cases the

contractor should construct a thrust block to distribute the forces