Page 374 - Trenchless Technology Piping Installation and Inspection

P. 374

324 Cha pte r Ei g h t

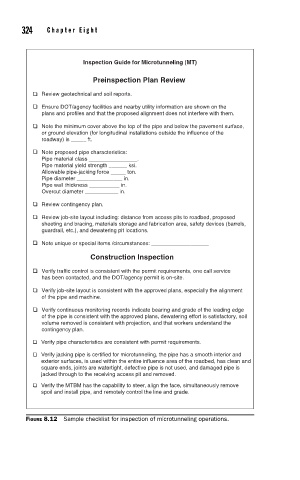

Inspection Guide for Microtunneling (MT)

Preinspection Plan Review

Review geotechnical and soil reports.

Ensure DOT/agency facilities and nearby utility information are shown on the

plans and profiles and that the proposed alignment does not interfere with them.

Note the minimum cover above the top of the pipe and below the pavement surface,

or ground elevation (for longitudinal installations outside the influence of the

roadway) is _____ ft.

Note proposed pipe characteristics:

Pipe material class ________________.

Pipe material yield strength ______ ksi.

Allowable pipe-jacking force _____ ton.

Pipe diameter _______________ in.

Pipe wall thickness __________ in.

Overcut diameter ___________ in.

Review contingency plan.

Review job-site layout including: distance from access pits to roadbed, proposed

sheeting and bracing, materials storage and fabrication area, safety devices (barrels,

guardrail, etc.), and dewatering pit locations.

Note unique or special items /circumstances: ___________________

Construction Inspection

Verify traffic control is consistent with the permit requirements, one call service

has been contacted, and the DOT/agency permit is on-site.

Verify job-site layout is consistent with the approved plans, especially the alignment

of the pipe and machine.

Verify continuous monitoring records indicate bearing and grade of the leading edge

of the pipe is consistent with the approved plans, dewatering effort is satisfactory, soil

volume removed is consistent with projection, and that workers understand the

contingency plan.

Verify pipe characteristics are consistent with permit requirements.

Verify jacking pipe is certified for microtunneling, the pipe has a smooth interior and

exterior surfaces, is used within the entire influence area of the roadbed, has clean and

square ends, joints are watertight, defective pipe is not used, and damaged pipe is

jacked through to the receiving access pit and removed.

Verify the MTBM has the capability to steer, align the face, simultaneously remove

spoil and install pipe, and remotely control the line and grade.

FIGURE 8.12 Sample checklist for inspection of microtunneling operations.