Page 391 - Trenchless Technology Piping Installation and Inspection

P. 391

Inspection and QA/QC for Trenchless Installation and Replacement Methods 341

Verify hammer frame is used to distribute ramming forces around the pipe

circumference, a launch seal is used at face of ramming operation, and a casing band

is applied to the leading edge of pipe in open-end ramming operations, or a cone-

shaped pipe head is attached to closed-end ramming operations.

Verify sufficient lubrication fluid quantity is used, and a lubrication system properly

injects lubricant on the inside and outside of the pipe.

Verify any unsuccessful rammed hole is back-filled immediately.

Verify each end of casing is bulkheaded, restoration is completed, and attach

Inspector’s Daily Report (IDR), form 2228.

Permit No. __________________________

Inspector: ___________________________

Date: _______________________________

FIGURE 8.21 Sample checklist for inspection of pipe ramming operations.

(Continued)

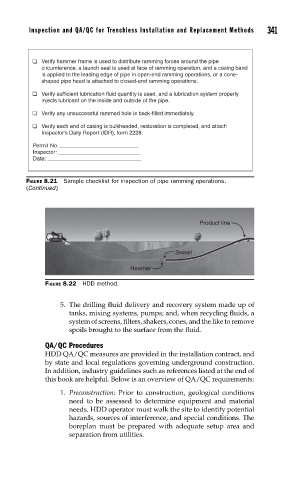

Product line

Swivel

Reamer

FIGURE 8.22 HDD method.

5. The drilling fluid delivery and recovery system made up of

tanks, mixing systems, pumps; and, when recycling fluids, a

system of screens, filters, shakers, cones, and the like to remove

spoils brought to the surface from the fluid.

QA/QC Procedures

HDD QA/QC measures are provided in the installation contract, and

by state and local regulations governing underground construction.

In addition, industry guidelines such as references listed at the end of

this book are helpful. Below is an overview of QA/QC requirements:

1. Preconstruction: Prior to construction, geological conditions

need to be assessed to determine equipment and material

needs. HDD operator must walk the site to identify potential

hazards, sources of interference, and special conditions. The

boreplan must be prepared with adequate setup area and

separation from utilities.