Page 49 - Trenchless Technology Piping Installation and Inspection

P. 49

22 Cha pte r O n e

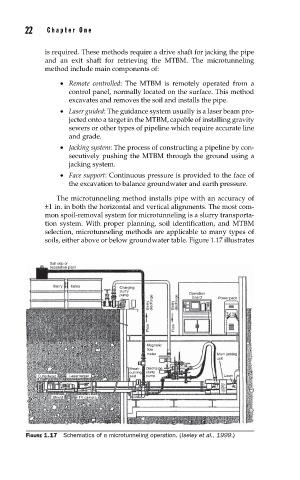

is required. These methods require a drive shaft for jacking the pipe

and an exit shaft for retrieving the MTBM. The microtunneling

method include main components of:

• Remote controlled: The MTBM is remotely operated from a

control panel, normally located on the surface. This method

excavates and removes the soil and installs the pipe.

• Laser guided: The guidance system usually is a laser beam pro-

jected onto a target in the MTBM, capable of installing gravity

sewers or other types of pipeline which require accurate line

and grade.

• Jacking system: The process of constructing a pipeline by con-

secutively pushing the MTBM through the ground using a

jacking system.

• Face support: Continuous pressure is provided to the face of

the excavation to balance groundwater and earth pressure.

The microtunneling method installs pipe with an accuracy of

±1 in. in both the horizontal and vertical alignments. The most com-

mon spoil-removal system for microtunneling is a slurry transporta-

tion system. With proper planning, soil identification, and MTBM

selection, microtunneling methods are applicable to many types of

soils, either above or below groundwater table. Figure 1.17 illustrates

Soil skip or

separation plant

Slurry Tanks Charging

slurry

pump Operation Power pack

board

Slurry discharge Slurry discharge

Flow Flow

Magnetic

flow

meter Main jacking

unit

Break- Discharge

out ring slurry

Cutterhead Laser target seal pump Laser

Shield TV camera

FIGURE 1.17 Schematics of a microtunneling operation. (Iseley et al., 1999.)