Page 191 - Tribology in Machine Design

P. 191

176 Tribology in machine design

Each equation shows that a velocity profile consists of a linear portion, the

second term to the right of the equals sign, and a parabolic portion which is

subtracted or added depending upon the sign of the first term. For velocity

u the second term is represented in Fig. 5.2 by a straight line drawn between

2

l/i and U 2. Since — (hy—y )/2fj, is always negative, the sign of the first term

is the opposite of the sign of dp/dx or dp/dz, which are the slopes of the

pressure versus the position curves. Notice the correspondence between the

positive, zero and negative slopes of the pressure curve, shown in Fig. 5.2,

and the concave (subtracted), straight and convex (added) profiles of the

Figure 5.2 velocity curves also shown in Fig. 5.2.

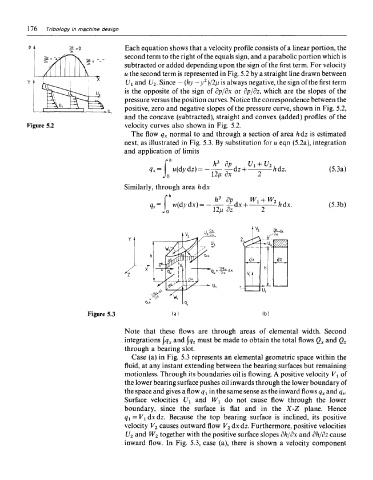

The flow q x normal to and through a section of area h dz is estimated

next, as illustrated in Fig. 5.3. By substitution for u eqn (5.2a), integration

and application of limits

Similarly, through area h dx

» L.

Figure 5.3

Note that these flows are through areas of elemental width. Second

integrations \q x and \q z must be made to obtain the total flows Q x and Q z

through a bearing slot.

Case (a) in Fig. 5.3 represents an elemental geometric space within the

fluid, at any instant extending between the bearing surfaces but remaining

motionless. Through its boundaries oil is flowing. A positive velocity V t of

the lower bearing surface pushes oil inwards through the lower boundary of

the space and gives a flow q v in the same sense as the inward flows q x and q z.

Surface velocities L^ and Wi do not cause flow through the lower

boundary, since the surface is flat and in the X-Z plane. Hence

q i = V ldxdz. Because the top bearing surface is inclined, its positive

velocity V 2 causes outward flow V 2 dx dz. Furthermore, positive velocities

1/2 and W 2 together with the positive surface slopes dh/dx and dh/dz cause

inward flow. In Fig. 5.3, case (a), there is shown a velocity component