Page 221 - Tribology in Machine Design

P. 221

206 Tribology in machine design

subsynchronous vibration at high speeds. Accurate manufacture of these

bearings is not always easy to obtain. A key parameter used in describing

these bearings is the fraction of converging pad to full pad length. Ratio a is

called the offset factor and is given by

a = converging pad length/pad arc length.

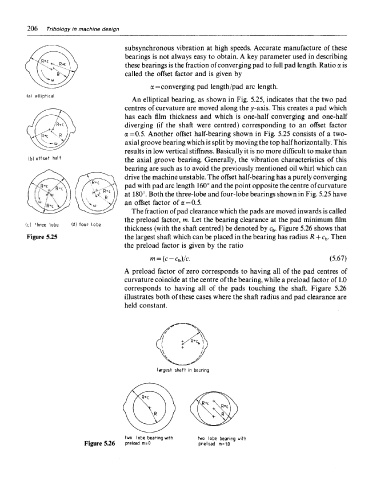

An elliptical bearing, as shown in Fig. 5.25, indicates that the two pad

centres of curvature are moved along the y-axis. This creates a pad which

has each film thickness and which is one-half converging and one-half

diverging (if the shaft were centred) corresponding to an offset factor

a =0.5. Another offset half-bearing shown in Fig. 5.25 consists of a two-

axial groove bearing which is split by moving the top half horizontally. This

results in low vertical stiffness. Basically it is no more difficult to make than

the axial groove bearing. Generally, the vibration characteristics of this

bearing are such as to avoid the previously mentioned oil whirl which can

drive the machine unstable. The offset half-bearing has a purely converging

pad with pad arc length 160° and the point opposite the centre of curvature

at 180°. Both the three-lobe and four-lobe bearings shown in Fig. 5.25 have

an offset factor of a =0.5.

The fraction of pad clearance which the pads are moved inwards is called

the preload factor, m. Let the bearing clearance at the pad minimum film

thickness (with the shaft centred) be denoted by c b. Figure 5.26 shows that

Figure 5.25 the largest shaft which can be placed in the bearing has radius R + c b. Then

the preload factor is given by the ratio

A preload factor of zero corresponds to having all of the pad centres of

curvature coincide at the centre of the bearing, while a preload factor of 1.0

corresponds to having all of the pads touching the shaft. Figure 5.26

illustrates both of these cases where the shaft radius and pad clearance are

held constant.

Figure 5.26