Page 223 - Tribology in Machine Design

P. 223

208 Tribology in machine design

Another important consideration for tilting pad bearings is the radial

location of the pad pivot point. It may be moved so that the pad centres-of-

curvature do not coincide at a point at the centre of the bearing. This is a

preload factor essentially the same as described for elliptical, three-, and

four-lobe bearings. A preload factor of less than zero (the pad centre-of-

curvature between the pad and bearing centre) creates a pad which will tend

to dig the leading edge into the shaft. This is sometimes called pad lock-up.

Lock-up can be prevented by placing a small bevel on the pad leading edge,

which produces a small converging wedge effect, but negative preloads

should be avoided.

Tilting pad bearings are very widely used to stabilize machines which

have subsynchronous vibration. Because the pads are free to follow the

shaft, the forces produced in the bearing are not capable of driving the shaft

in an unstable mode. Their disadvantages include high cost, high horse-

power loss and installation problems. Tilting pad journal bearings have

been widely adapted, particularly in cases where they are not readily

accessible and maintenance of alignment is important.

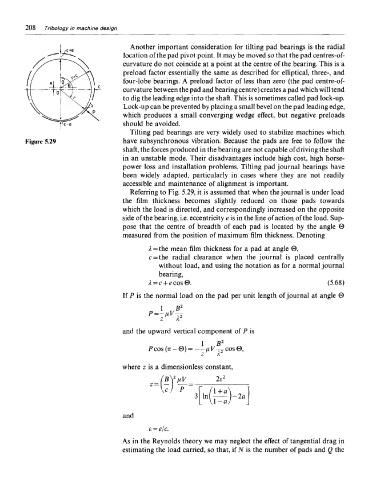

Referring to Fig. 5.29, it is assumed that when the journal is under load

the film thickness becomes slightly reduced on those pads towards

which the load is directed, and correspondingly increased on the opposite

side of the bearing, i.e. eccentricity e is in the line of action of the load. Sup-

pose that the centre of breadth of each pad is located by the angle 0

measured from the position of maximum film thickness. Denoting

A = the mean film thickness for a pad at angle 0,

c = the radial clearance when the journal is placed centrally

without load, and using the notation as for a normal journal

bearing,

If P is the normal load on the pad per unit length of journal at angle 0

and the upward vertical component of P is

where z is a dimensionless constant,

and

As in the Reynolds theory we may neglect the effect of tangential drag in

estimating the load carried, so that, if N is the number of pads and Q the