Page 45 - Tribology in Machine Design

P. 45

32 Tribology in machine design

greatly accelerates fatigue, for example, by hydrogen embrittlement of iron,

so that V fc will tend to be large and positive. On the other hand, adhesion

and fatigue rarely, if ever, coexist, and this is presumably because adhesive

wear destroys the microcracks from which fatigue propagates. Hence, the

wear volume F fa due to the interaction between fatigue and adhesion will

always be zero. Since adhesion and corrosion are dimensionally similar, it

may be hoped that K ac and K fac will prove to be negligible. If this is so, only

F fc needs to be evaluated. By assuming that the lubricant is not corrosive

and that the environment is not excessively humid, it is possible to simplify

eqn (2.50) further, and to reduce it to the form

According to the model presented here adhesive wear takes place on the

metal-metal contact area, A m, whereas fatigue wear should take place on

the remaining real area of contact, that is, A r — A m. Repeated stressing

through the thin adsorbed lubricant film existing on these micro-areas of

contact would be expected to produce fatigue wear.

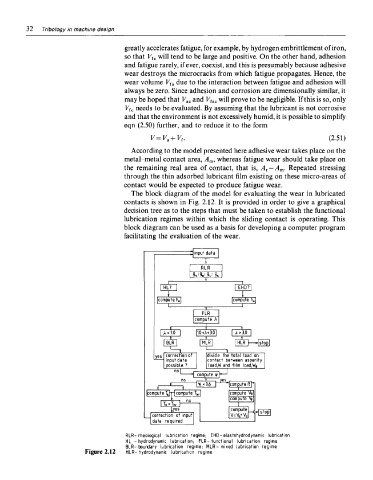

The block diagram of the model for evaluating the wear in lubricated

contacts is shown in Fig. 2.12. It is provided in order to give a graphical

decision tree as to the steps that must be taken to establish the functional

lubrication regimes within which the sliding contact is operating. This

block diagram can be used as a basis for developing a computer program

facilitating the evaluation of the wear.

RLR-Theological lubrication regime; EHD-elastohydrodynamic lubrication

HL - hydrodynamic lubrication; FLR-functional lubrication regime

BLR-boundary lubrication regime; MLR- mixed lubrication regime

Figure 2.12 HLR-hydrodynamic lubrication regime