Page 204 - Tunable Lasers Handbook

P. 204

182 F. J. Duarte

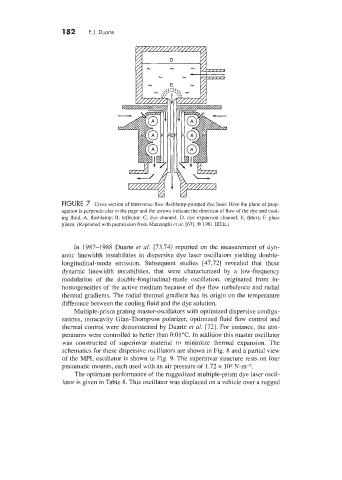

FIGURE 7 Cross section of transverse-flow flashlamp-pumped dye laser. Here the plane of prop-

agation is perpendicular to the page and th2 arrows indicate the direction of flow of the dye and cool-

ing fluid. A, flashlamp; B, reflector: C. dye channel: D, dye expansion channel; E. filters; E glass

plates. (Reprinted with permission from Mazzinghi ef ul. [67]. D 1981 IEEE.)

In 1987-1988 Duarte et al. [73.74] reported on the measurement of dyn-

amic linewidth instabilities in dispersive dye laser oscillators yielding double-

longitudinal-mode emission. Subsequent studies [47,72] revealed that these

dynamic linewidth instabilities, that were characterized by a low-frequency

modulation of the double-longitudinal-mode oscillation, originated from in-

homogeneities of the active medium because of dye flow turbulence and radial

thermal gradients. The radial thermal gradient has its origin on the temperature

difference between the cooling fluid and the dye solution.

Multiple-prism grating master-oscillators with optimized dispersive configu-

rations, intracavity Glan-Thompson polarizer, optimized fluid flow control and

thermal control were demonstrated by Duarte et al. [72]. For instance, the tem-

peratures were controlled to better than 0.01"C. In addition this master oscillator

was constructed of superinvar material to minimize thermal expansion. The

schematics for these dispersive oscillators are shown in Fig. 8 and a partial view

of the MPL oscillator is shown in Fig. 9. The superinvar structure rests on four

pneumatic mounts, each used with an air pressure of 1.72 x 105 N-m-2.

The optimum performance of the ruggedized multiple-prism dye laser oscil-

lator is given in Table 8. This oscillator was displaced on a vehicle over a rugged