Page 113 - Uninterruptible Power Supplies

P. 113

Additional Information Relating to the Standby Supply Installation

Additional Information Relating to the Standby Supply Installation 111

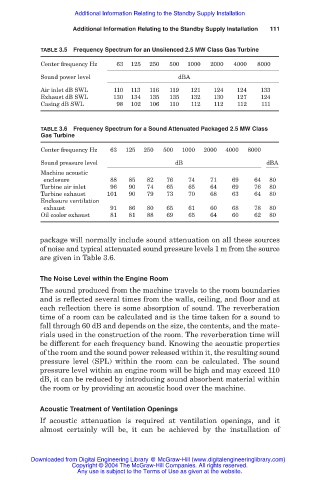

TABLE 3.5 Frequency Spectrum for an Unsilenced 2.5 MW Class Gas Turbine

Center frequency Hz 63 125 250 500 1000 2000 4000 8000

Sound power level dBA

Air inlet dB SWL 110 113 116 119 121 124 124 133

Exhaust dB SWL 130 134 135 135 132 130 127 124

Casing dB SWL 98 102 106 110 112 112 112 111

TABLE 3.6 Frequency Spectrum for a Sound Attenuated Packaged 2.5 MW Class

Gas Turbine

Center frequency Hz 63 125 250 500 1000 2000 4000 8000

Sound pressure level dB dBA

Machine acoustic

enclosure 88 85 82 76 74 71 69 64 80

Turbine air inlet 96 90 74 65 65 64 69 76 80

Turbine exhaust 101 90 79 73 70 68 63 64 80

Enclosure ventilation

exhaust 91 86 80 65 61 60 68 78 80

Oil cooler exhaust 81 81 88 69 65 64 60 62 80

package will normally include sound attenuation on all these sources

of noise and typical attenuated sound pressure levels 1 m from the source

are given in Table 3.6.

The Noise Level within the Engine Room

The sound produced from the machine travels to the room boundaries

and is reflected several times from the walls, ceiling, and floor and at

each reflection there is some absorption of sound. The reverberation

time of a room can be calculated and is the time taken for a sound to

fall through 60 dB and depends on the size, the contents, and the mate-

rials used in the construction of the room. The reverberation time will

be different for each frequency band. Knowing the acoustic properties

of the room and the sound power released within it, the resulting sound

pressure level (SPL) within the room can be calculated. The sound

pressure level within an engine room will be high and may exceed 110

dB, it can be reduced by introducing sound absorbent material within

the room or by providing an acoustic hood over the machine.

Acoustic Treatment of Ventilation Openings

If acoustic attenuation is required at ventilation openings, and it

almost certainly will be, it can be achieved by the installation of

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.