Page 116 - Valve Selection Handbook

P. 116

Manual Valves 103

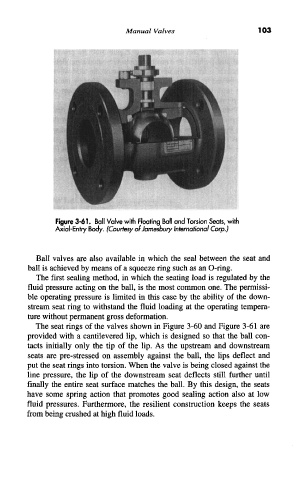

Figure 3-61. Ball Valve with Floating Ball and Torsion Seats, with

Axial-Entry Body. (Courtesy ofJamesbury International Corp.)

Ball valves are also available in which the seal between the seat and

ball is achieved by means of a squeeze ring such as an O-ring.

The first sealing method, in which the seating load is regulated by the

fluid pressure acting on the ball, is the most common one. The permissi-

ble operating pressure is limited in this case by the ability of the down-

stream seat ring to withstand the fluid loading at the operating tempera-

ture without permanent gross deformation.

The seat rings of the valves shown in Figure 3-60 and Figure 3-61 are

provided with a cantilevered lip, which is designed so that the ball con-

tacts initially only the tip of the lip. As the upstream and downstream

seats are pre-stressed on assembly against the ball, the lips deflect and

put the seat rings into torsion. When the valve is being closed against the

line pressure, the lip of the downstream seat deflects still further until

finally the entire seat surface matches the ball. By this design, the seats

have some spring action that promotes good sealing action also at low

fluid pressures. Furthermore, the resilient construction keeps the seats

from being crushed at high fluid loads.