Page 151 - Valve Selection Handbook

P. 151

138 Valve Selection Handbook

the pressures on the diaphragm. When using these valves for high vacu-

um, the manufacturer should be consulted.

Straight-through diaphragm valves are also available with full-bore

and reduced-bore flow passage. In the case of reduced-bore valves, the

bonnet assembly of the next smaller valve is used. For example, a DN 50

(NFS 2) reduced-bore valve is fitted with a DN 40 (NFS 1H) bonnet. The

construction of the bonnet is otherwise similar to that of weir-type

diaphragm valves.

The size range of straight-through diaphragm valves typically covers

valves up to DN 350 (NFS 14).

Construction Materials

The valve body of diaphragm valves is available in a great variety of

construction materials, including plastics, to meet service requirements.

The simple body shape also lends itself readily to lining with a great

variety of corrosion-resistant materials, leading often to low-cost solu-

tions for an otherwise expensive valve.

Because the diaphragm separates the bonnet from the flowing fluid,

the bonnet is normally made of cast iron and epoxy coated inside and

outside. If requested, the bonnet is available also in a variety of other

materials.

Diaphragms are available in a great variety of elastomers and plastics.

Valve makers' catalogs advise the user on the selection of the diaphragm

material for a given application.

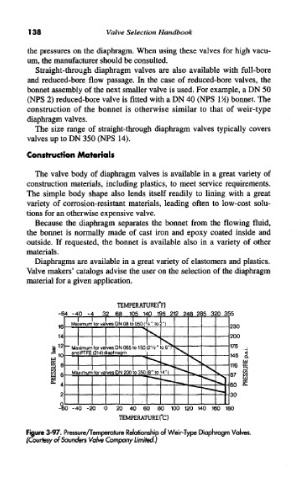

Figure 3-97. Pressure/Temperature Relationship of Weir-Type Diaphragm Valves.

(Courtesy of Sounders Valve Company limited.)