Page 218 - Valve Selection Handbook

P. 218

Pressure Relief Valves 205

system fluid and therefore do not suffer thermal shock on valve opening.

Second, solids carried by the discharging fluid do not impact directly on

the seating surface of the piston. Location of the piston within the pres-

sure zone therefore significantly reduces potential seating damage. The

opening and closing deceleration of the piston is controlled in this case

by built-in dampers to limit mechanical shock on valve and piping sys-

tem on valve opening and closing.

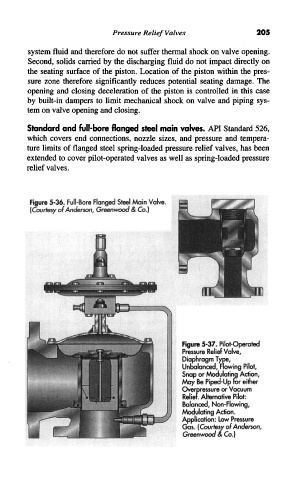

Standard and full-bore flanged steel main valves. API Standard 526,

which covers end connections, nozzle sizes, and pressure and tempera-

ture limits of flanged steel spring-loaded pressure relief valves, has been

extended to cover pilot-operated valves as well as spring-loaded pressure

relief valves.

Figure 5-36. Full-Bore Flanged Steel Main Valve.

(Courtesy of Anderson, Greenwood & Co.)

Figure 5-37. Pilot-Operated

Pressure Relief Valve,

Diaphragm Type,

Unbalanced, Flowing Pilot,

Snap or Modulating Action,

May Be Piped-Up for either

Overpressure or Vacuum

Relief. Alternative Pilot:

Balanced, Non-Flowing,

Modulating Action.

Application: Low Pressure

Gas. (Courtesy of Anderson,

Greenwood & Co.)