Page 243 - Valve Selection Handbook

P. 243

230 Valve Selection Handbook

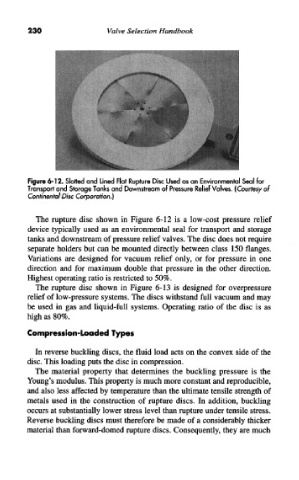

Figure 6-12. Slotted and Lined Flat Rupture Disc Used as an Environmental Seal for

Transport and Storage Tanks and Downstream of Pressure Relief Valves. (Courtesy of

Continental Disc Corporation.)

The rupture disc shown in Figure 6-12 is a low-cost pressure relief

device typically used as an environmental seal for transport and storage

tanks and downstream of pressure relief valves. The disc does not require

separate holders but can be mounted directly between class 150 flanges.

Variations are designed for vacuum relief only, or for pressure in one

direction and for maximum double that pressure in the other direction.

Highest operating ratio is restricted to 50%.

The rupture disc shown in Figure 6-13 is designed for overpressure

relief of low-pressure systems. The discs withstand full vacuum and may

be used in gas and liquid-full systems. Operating ratio of the disc is as

high as 80%.

Compression-Loaded Types

In reverse buckling discs, the fluid load acts on the convex side of the

disc. This loading puts the disc in compression.

The material property that determines the buckling pressure is the

Young's modulus. This property is much more constant and reproducible,

and also less affected by temperature than the ultimate tensile strength of

metals used in the construction of rupture discs. In addition, buckling

occurs at substantially lower stress level than rupture under tensile stress.

Reverse buckling discs must therefore be made of a considerably thicker

material than forward-domed rupture discs. Consequently, they are much