Page 63 - Valve Selection Handbook

P. 63

50 Valve Selection Handbook

rating of welding end valves corresponds frequently to the rating of

flanged valves. However, standards may permit welding end valves to be

36

designed to special ratings that meet the actual operating conditions. If

the valve contains components made of polymeric materials, the pressure-

temperature relationship is limited, as determined by the properties of the

polymeric material. Some standards for valves containing such materials

as ball valves specify pressure-temperature limits for the valve. Where

such standards do not exist, it is the manufacturer's responsibility to state

the pressure and temperature limitations of the valve.

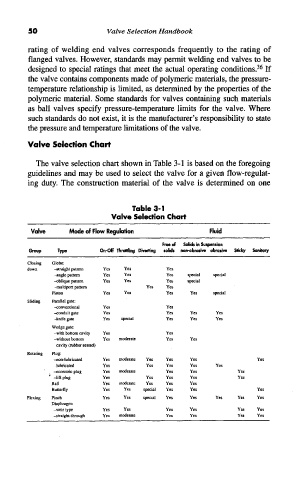

Valve Selection Chart

The valve selection chart shown in Table 3-1 is based on the foregoing

guidelines and may be used to select the valve for a given flow-regulat-

ing duty. The construction material of the valve is determined on one

Table 3-1

Valve Selection Chart

Valve Mode of Flow Regulation Fluid

Free of Solids in Suspension

Group Type On-Off Throttling Diverting solids non-abrasive abrasive Sticky Sanitary

Closing Globe:

down -straight pattern Yes Yes Yes

-angle pattern Yes Yes Yes special special

-oblique pattern Yes Yes Yes special

-multiport pattern Yes Yes

Piston Yes Yes Yes Yes special

Sliding Parallel gate:

-conventional Yes Yes

-conduit gate Yes Yes Yes Yes

-knife gate Yes special Yes Yes Yes

Wedge gate:

-with bottom cavity Yes Yes

-without bottom Yes moderate Yes Yes

cavity (rubber seated)

Rotating Plug:

-non-lubricated Yes moderate Yes Yes Yes Yes

-lubricated Yes Yes Yes Yes Yes

-eccentric plug Yes moderate Yes Yes Yes

-lift plug Yes Yes Yes Yes Yes

Ball Yes moderate Yes Yes Yes

Butterfly Yes Yes special Yes Yes Yes

Flexing Pinch Yes Yes special Yes Yes Yes Yes Yes

Diaphragm:

-weir type Yes Yes Yes Yes Yes Yes

-straight-through Yes moderate Yes Yes Yes Yes