Page 67 - Valve Selection Handbook

P. 67

54 Valve Selection Handbook

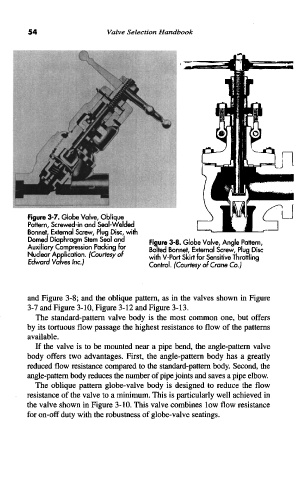

Figure 3-7. Globe Valve, Oblique

Pattern, Screwed-in and Seal-Welded

Bonnet, External Screw, Plug Disc, with

Domed Diaphragm Stem Seal and Figure 3-8. Globe Valve, Angle Pattern,

Auxiliary Compression Packing for Bolted Bonnet, External Screw, Plug Disc

Nuclear Application. (Courtesy of with V-Port Skirt for Sensitive Throttling

Edward Valves Inc.)

Control. (Courtesy of Crane Co.)

and Figure 3-8; and the oblique pattern, as in the valves shown in Figure

3-7 and Figure 3-10, Figure 3-12 and Figure 3-13.

The standard-pattern valve body is the most common one, but offers

by its tortuous flow passage the highest resistance to flow of the patterns

available.

If the valve is to be mounted near a pipe bend, the angle-pattern valve

body offers two advantages. First, the angle-pattern body has a greatly

reduced flow resistance compared to the standard-pattern body. Second, the

angle-pattern body reduces the number of pipe joints and saves a pipe elbow.

The oblique pattern globe-valve body is designed to reduce the flow

resistance of the valve to a minimum. This is particularly well achieved in

the valve shown in Figure 3-10. This valve combines low flow resistance

for on-off duty with the robustness of globe-valve seatings.