Page 72 - Valve Selection Handbook

P. 72

Manual Valves 59

The performance of such seatings may be improved by hollowing out

the disc to impart some elasticity to the disc shell, as is done in the valve

shown in Figure 3-11. This elasticity permits the disc to adapt more read-

ily to deviations of the seatings from roundness.

The seatings shown in Figure 3-15d are ball shaped at the disc and

tapered at the seat. The disc can therefore roll, to some extent, on the seat

until seat and disc are aligned. Because the contact between the seatings

approaches that of a line, the seating stress is very high. On the debit

side, the line contact is prone to damage from erosion. The ball-shaped

seatings are therefore used only for dry gases, which are also free of

solids. This construction is used mainly by U.S. manufacturers.

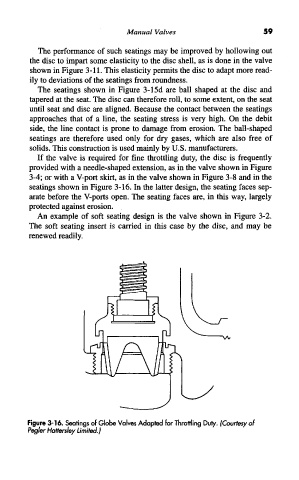

If the valve is required for fine throttling duty, the disc is frequently

provided with a needle-shaped extension, as in the valve shown in Figure

3-4; or with a V-port skirt, as in the valve shown in Figure 3-8 and in the

seatings shown in Figure 3-16. In the latter design, the seating faces sep-

arate before the V-ports open. The seating faces are, in this way, largely

protected against erosion.

An example of soft seating design is the valve shown in Figure 3-2.

The soft seating insert is carried in this case by the disc, and may be

renewed readily.

Figure 3-16. Seatings of Globe Valves Adapted for Throttling Duty. (Courtesy of

Pegler Hattersley Limited.)