Page 75 - Valve Selection Handbook

P. 75

62 Valve Selection Handbook

the joint. The bonnet seal therefore becomes tighter as the fluid pressure

increases. This construction principle is frequently preferred for large

valves operating at high pressures and temperatures.

Small globe valves may avoid the bonnet joint altogether, as in the

valve shown in Figure 3-5 and Figure 3-11. Access to the valve internals

is through the gland opening, which is large enough to pass the valve

components.

Stuffing Boxes and Back Seating

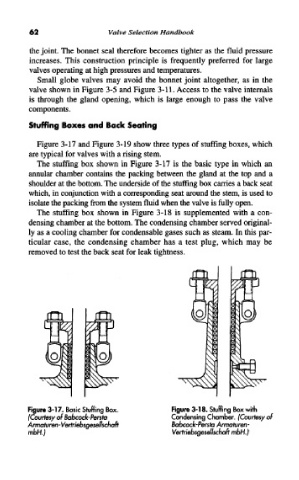

Figure 3-17 and Figure 3-19 show three types of stuffing boxes, which

are typical for valves with a rising stem.

The stuffing box shown in Figure 3-17 is the basic type in which an

annular chamber contains the packing between the gland at the top and a

shoulder at the bottom. The underside of the stuffing box carries a back seat

which, in conjunction with a corresponding seat around the stem, is used to

isolate the packing from the system fluid when the valve is fully open.

The stuffing box shown in Figure 3-18 is supplemented with a con-

densing chamber at the bottom. The condensing chamber served original-

ly as a cooling chamber for condensable gases such as steam. In this par-

ticular case, the condensing chamber has a test plug, which may be

removed to test the back seat for leak tightness.

Figure 3-17. Basic Stuffing Box. Figure 3-18. Stuffing Box with

(Courtesy of Babcock-Persta Condensing Chamber. (Courtesy of

Armaturen-Vertriebsgesellschaft Babcock-Persta Armaturen-

mbH.) Vertriebsgesellscrtaft mbH.)