Page 234 - Vogel's TEXTBOOK OF QUANTITATIVE CHEMICAL ANALYSIS

P. 234

7 ION EXCHANCE

of the liquid does not fa11 below the top of the resin bed, so that the latter is

always wholly immersed in the liquid. The ratio of the height of the column to

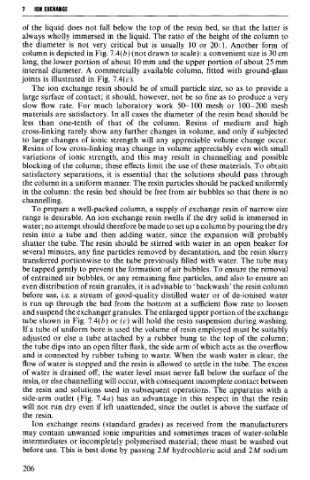

the diameter is not very critical but is usually 10 or 20: 1. Another form of

column is depicted in Fig. 7.4(b) (not drawn to scale): a convenient size is 30 cm

long, the lower portion of about 10 mm and the upper portion of about 25 mm

interna1 diameter. A commercially available column, fitted with ground-glass

joints is illustrated in Fig. 7.4(c).

The ion exchange resin should be of small particle size, so as to provide a

large surface of contact; it should, however, not be so fine as to produce a very

slow flow rate. For much laboratory work 50-100 mesh or 100-200 mesh

materials are satisfactory. In al1 cases the diameter of the resin bead should be

less than one-tenth of that of the column. Resins of medium and high

cross-linking rarely show any further changes in volume, and only if subjected

to large changes of ionic strength will any appreciable volume change occur.

Resins of low cross-linking may change in volume appreciably even with small

variations of ionic strength, and this may result in channelling and possible

blocking of the column; these effects limit the use of these materials. To obtain

satisfactory separations, it is essential that the solutions should pass through

the column in a uniform manner. The resin particles should be packed uniformly

in the column: the resin bed should be free from air bubbles so that there is no

channelling.

To prepare a well-packed column, a supply of exchange resin of narrow size

range is desirable. An ion exchange resin swells if the dry solid is immersed in

water; no attempt should therefore be made to set up a column by pouring the dry

resin into a tube and then adding water, since the expansion will probably

shatter the tube. The resin should be stirred with water in an open beaker for

several minutes, any fine particles removed by decantation, and the resin slurry

transferred portionwise to the tube previously filled with water. The tube may

be tapped gently to prevent the formation of air bubbles. To ensure the removal

of entrained air bubbles, or any remaining fine particles, and also to ensure an

even distribution of resin granules, it is advisable to 'backwash' the resin column

before use, i.e. a Stream of good-quality distilled water or of de-ionised water

is run up through the bed from the bottom at a sufficient flow rate to loosen

and suspend the exchanger granules. The enlarged upper portion of the exchange

tube shown in Fig. 7.4(b) or (c) will hold the resin suspension during washing.

If a tube of uniform bore is used the volume of resin employed must be suitably

adjusted or else a tube attached by a rubber bung to the top of the column;

the tube dips into an open filter flask, the side arm of which acts as the overflow

and is connected by rubber tubing to waste. When the wash water is clear, the

flow of water is stopped and the resin is allowed to settle in the tube. The excess

of water is drained off; the water level must never fa11 below the surface of the

resin, or else channelling will occur, with consequent incomplete contact between

the resin and solutions used in subsequent operations. The apparatus with a

side-arm outlet (Fig. 7.4~) has an advantage in this respect in that the resin

will not run dry even if left unattended, since the outlet is above the surface of

the resin.

Ion exchange resins (standard grades) as received from the manufacturers

may contain unwanted ionic impurities and sometimes traces of water-soluble

intermediates or incompletely polymerised material; these must be washed out

before use. This is best done by passing 2M hydrochloric acid and 2M sodium