Page 297 - Materials Chemistry, Second Edition

P. 297

CAT3525_C09.qxd 2/8/2005 10:11 AM Page 268

268 Waste Management Practices: Municipal, Hazardous, and Industrial

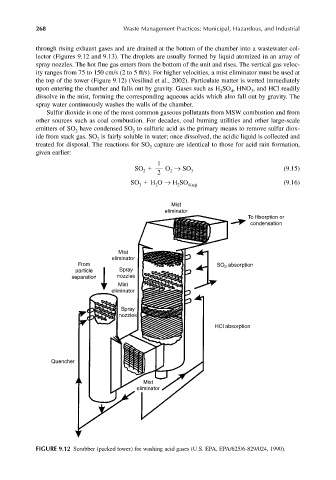

through rising exhaust gases and are drained at the bottom of the chamber into a wastewater col-

lector (Figures 9.12 and 9.13). The droplets are usually formed by liquid atomized in an array of

spray nozzles. The hot flue gas enters from the bottom of the unit and rises. The vertical gas veloc-

ity ranges from 75 to 150 cm/s (2 to 5 ft/s). For higher velocities, a mist eliminator must be used at

the top of the tower (Figure 9.12) (Vesilind et al., 2002). Particulate matter is wetted immediately

upon entering the chamber and falls out by gravity. Gases such as H SO , HNO , and HCl readily

4

3

2

dissolve in the mist, forming the corresponding aqueous acids which also fall out by gravity. The

spray water continuously washes the walls of the chamber.

Sulfur dioxide is one of the most common gaseous pollutants from MSW combustion and from

other sources such as coal combustion. For decades, coal burning utilities and other large-scale

emitters of SO have condensed SO to sulfuric acid as the primary means to remove sulfur diox-

2

2

ide from stack gas. SO is fairly soluble in water; once dissolved, the acidic liquid is collected and

2

treated for disposal. The reactions for SO capture are identical to those for acid rain formation,

2

given earlier:

1

SO O → SO (9.15)

2

2 2 3

SO H O → H SO 4(aq) (9.16)

3

2

2

Mist

eliminator

To filsorption or

condensation

Mist

eliminator

From SO 2 absorption

particle Spray

separation nozzles

Mist

eliminator

Spray

nozzles

HCl absorption

Quencher

Mist

eliminator

FIGURE 9.12 Scrubber (packed tower) for washing acid gases (U.S. EPA, EPA/625/6-829/024, 1990).