Page 81 - Wastewater Solids Incineration Systems

P. 81

50 Wastewater Solids Incineration Systems

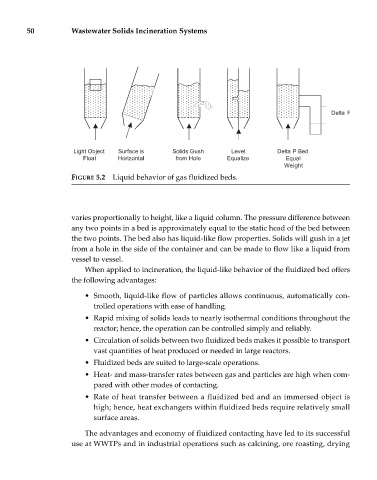

FIGURE 5.2 Liquid behavior of gas fluidized beds.

varies proportionally to height, like a liquid column. The pressure difference between

any two points in a bed is approximately equal to the static head of the bed between

the two points. The bed also has liquid-like flow properties. Solids will gush in a jet

from a hole in the side of the container and can be made to flow like a liquid from

vessel to vessel.

When applied to incineration, the liquid-like behavior of the fluidized bed offers

the following advantages:

• Smooth, liquid-like flow of particles allows continuous, automatically con-

trolled operations with ease of handling.

• Rapid mixing of solids leads to nearly isothermal conditions throughout the

reactor; hence, the operation can be controlled simply and reliably.

• Circulation of solids between two fluidized beds makes it possible to transport

vast quantities of heat produced or needed in large reactors.

• Fluidized beds are suited to large-scale operations.

• Heat- and mass-transfer rates between gas and particles are high when com-

pared with other modes of contacting.

• Rate of heat transfer between a fluidized bed and an immersed object is

high; hence, heat exchangers within fluidized beds require relatively small

surface areas.

The advantages and economy of fluidized contacting have led to its successful

use at WWTPs and in industrial operations such as calcining, ore roasting, drying