Page 40 - Water Engineering Hydraulics, Distribution and Treatment

P. 40

18

Chapter 1

Introduction to Water Systems

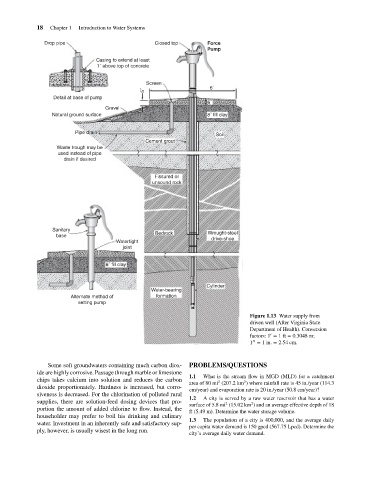

Drop pipe

Pump

1˝ above top of concrete

Screen

6´

5˝

Detail at base of pump

6˝

Gravel

Natural ground surface

8˝ fill clay

Pipe drain Casing to extend at least Closed top Force

Soil

Cement grout

Waste trough may be

used instead of pipe

drain if desired

Fissured or

unsound rock

Sanitary Wrought-steel

base Bedrock drive-shoe

Watertight

joint

8˝ fill clay

Cylinder

Water-bearing

Alternate method of formation

setting pump

Figure 1.13 Water supply from

driven well (After Virginia State

Department of Health). Conversion

′

factors: 1 = 1ft = 0.3048 m;

′′

1 = 1in. = 2.54 cm.

Some soft groundwaters containing much carbon diox- PROBLEMS/QUESTIONS

ide are highly corrosive. Passage through marble or limestone

1.1 What is the stream flow in MGD (MLD) for a catchment

chips takes calcium into solution and reduces the carbon

2

2

area of 80 mi (207.2 km ) where rainfall rate is 45 in./year (114.3

dioxide proportionately. Hardness is increased, but corro-

cm/year) and evaporation rate is 20 in./year (50.8 cm/year)?

siveness is decreased. For the chlorination of polluted rural

1.2 A city is served by a raw water reservoir that has a water

supplies, there are solution-feed dosing devices that pro-

2

2

surface of 5.8 mi (15.02 km ) and an average effective depth of 18

portion the amount of added chlorine to flow. Instead, the

ft (5.49 m). Determine the water storage volume.

householder may prefer to boil his drinking and culinary

1.3 The population of a city is 400,000, and the average daily

water. Investment in an inherently safe and satisfactory sup-

per capita water demand is 150 gpcd (567.75 Lpcd). Determine the

ply, however, is usually wisest in the long run.

city’s average daily water demand.