Page 316 - Water Loss Control

P. 316

Contr olling Real Losses in the Field—Pr oactive Leak Detection 285

• The configuration of the distribution network pump system and location of

pumping stations need to be carefully assessed and included in the design

stage.

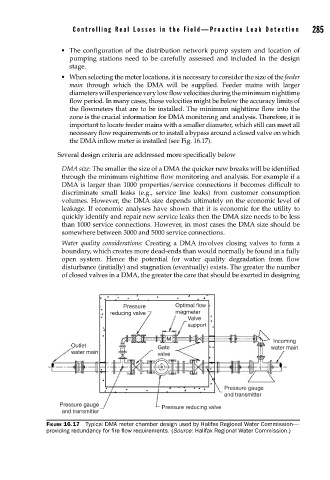

• When selecting the meter locations, it is necessary to consider the size of the feeder

main through which the DMA will be supplied. Feeder mains with larger

diameters will experience very low flow velocities during the minimum nighttime

flow period. In many cases, those velocities might be below the accuracy limits of

the flowmeters that are to be installed. The minimum nighttime flow into the

zone is the crucial information for DMA monitoring and analysis. Therefore, it is

important to locate feeder mains with a smaller diameter, which still can meet all

necessary flow requirements or to install a bypass around a closed valve on which

the DMA inflow meter is installed (see Fig. 16.17).

Several design criteria are addressed more specifically below

DMA size: The smaller the size of a DMA the quicker new breaks will be identified

through the minimum nighttime flow monitoring and analysis. For example if a

DMA is larger than 1000 properties/service connections it becomes difficult to

discriminate small leaks (e.g., service line leaks) from customer consumption

volumes. However, the DMA size depends ultimately on the economic level of

leakage. If economic analyses have shown that it is economic for the utility to

quickly identify and repair new service leaks then the DMA size needs to be less

than 1000 service connections. However, in most cases the DMA size should be

somewhere between 3000 and 5000 service connections.

Water quality considerations: Creating a DMA involves closing valves to form a

boundary, which creates more dead-ends than would normally be found in a fully

open system. Hence the potential for water quality degradation from flow

disturbance (initially) and stagnation (eventually) exists. The greater the number

of closed valves in a DMA, the greater the care that should be exerted in designing

Pressure Optimal flow

reducing valve magmeter

Valve

support

M Incoming

Outlet Gate water main

water main valve

Pressure gauge

and transmitter

Pressure gauge Pressure reducing valve

and transmitter

FIGURE 16.17 Typical DMA meter chamber design used by Halifax Regional Water Commission—

providing redundancy for fi re fl ow requirements. (Source: Halifax Regional Water Commission.)