Page 368 - Water and wastewater engineering

P. 368

REVERSE OSMOSIS AND NANOFILTRATION 9-7

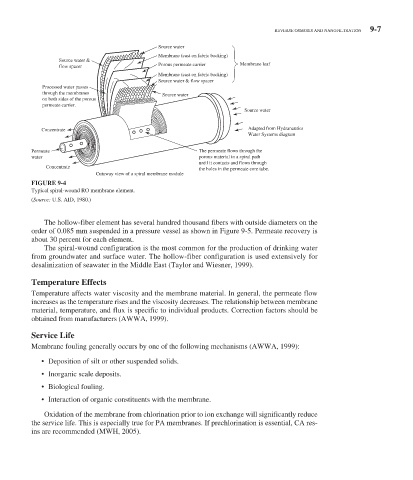

Source water

Membrane (cast on fabric backing)

Source water &

Porous permeate carrier Membrane leaf

flow spacer

Membrane (cast on fabric backing)

Source water & flow spacer

Processed water passes

through the membranes

Source water

on both sides of the porous

permeate carrier.

Source water

Concentrate Adapted from Hydranautics

Water Systems diagram

Permeate The permeate flows through the

water porous material in a spiral path

until it contacts and flows through

Concentrate

the holes in the permeate core tube.

Cutaway view of a spiral membrane module

FIGURE 9-4

Typical spiral-wound RO membrane element.

( Source: U.S. AID, 1980.)

The hollow-fiber element has several hundred thousand fibers with outside diameters on the

order of 0.085 mm suspended in a pressure vessel as shown in Figure 9-5 . Permeate recovery is

about 30 percent for each element.

The spiral-wound configuration is the most common for the production of drinking water

from groundwater and surface water. The hollow-fiber configuration is used extensively for

desalinization of seawater in the Middle East (Taylor and Wiesner, 1999).

Temperature Effects

Temperature affects water viscosity and the membrane material. In general, the permeate flow

increases as the temperature rises and the viscosity decreases. The relationship between membrane

material, temperature, and flux is specific to individual products. Correction factors should be

obtained from manufacturers (AWWA, 1999).

Service Life

Membrane fouling generally occurs by one of the following mechanisms (AWWA, 1999):

• Deposition of silt or other suspended solids.

• Inorganic scale deposits.

• Biological fouling.

• Interaction of organic constituents with the membrane.

Oxidation of the membrane from chlorination prior to ion exchange will significantly reduce

the service life. This is especially true for PA membranes. If prechlorination is essential, CA res-

ins are recommended (MWH, 2005).