Page 429 - Water and wastewater engineering

P. 429

11-2 WATER AND WASTEWATER ENGINEERING

11-1 INTRODUCTION

Settled water turbidity is generally in the range from 1 to 10 NTU with a typical value being

2 NTU. Because these levels of turbidity interfere with the subsequent disinfection processes,

the turbidity must be reduced. The Interim Enhanced Surface Water Treatment Rule (IESWTR)

promulgated by the U.S. Environmental Protection Agency (EPA) requires that the treated water

turbidity level be 0.3 NTU in 95 percent of monthly measurements with no sample to exceed 1

NTU. In order to reduce the turbidity to this level, a filtration process is normally used. The most

common filtration process is granular filtration where the suspended or colloidal impurities are

separated from water by passage through a porous medium. The medium is usually a bed of sand

or other media such as coal, activated carbon, or garnet. In the last two decades, filters composed

of membranes have been employed with increasing frequency. Granular filtration process are the

subject of this chapter. Membrane processes are discussed in Chapter 12.

11-2 AN OVERVIEW OF THE FILTRATION PROCESS

A number of classification systems are used to describe granular filters including media type,

filtration rate, washing technique, and filtration rate control. This discussion is limited to slow

sand, rapid sand, and high-rate filters with either multimedia or deep monomedium the focus

is on rapid sand and high-rate filters. Pressure filters (also called precoat filters) and automatic

backwash filters are not discussed. Discussion of these types of filters may be found in Cleasby

and Logsdon, 1999; Kawamura, 2000; MWH, 2005; Reynolds and Richards, 1996.

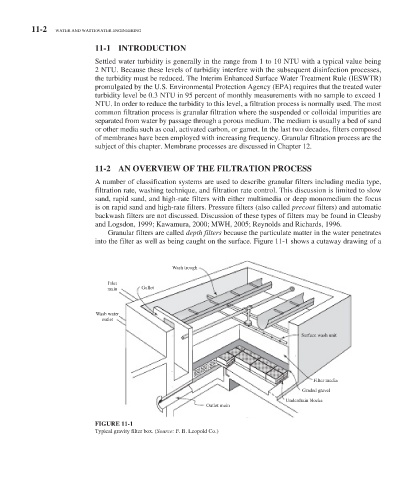

Granular filters are called depth filters because the particulate matter in the water penetrates

into the filter as well as being caught on the surface. Figure 11-1 shows a cutaway drawing of a

Wash trough

Inlet

main Gullet

Wash water

outlet

Surface wash unit

Filter media

Graded gravel

Underdrain blocks

Outlet main

FIGURE 11-1

Typical gravity filter box. ( Source: F. B. Leopold Co.)