Page 39 - Welding Robots Technology, System Issues, and Applications

P. 39

Introduction and Overview

23

In conclusion, the majority of industrial welding applications benefit from the

introduction of robot manipulators, since most of the deficiencies, attributed to the

human factor, are removed with advantages when robots are introduced. Also, the

welding process is very dangerous and demanding in precision and operator

attention, requiring substantial physical efforts from operators, which makes it a

good candidate for robots.

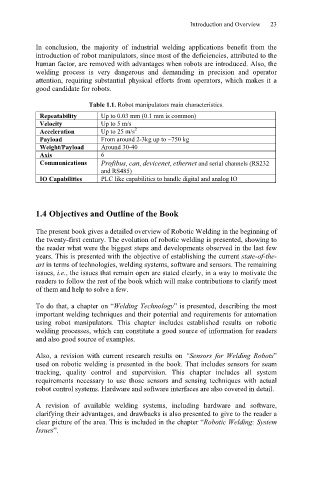

Table 1.1. Robot manipulators main characteristics.

Repeatability Up to 0.03 mm (0.1 mm is common)

Velocity Up to 5 m/s

2

Acceleration Up to 25 m/s

Payload From around 2-3kg up to ~750 kg

Weight/Payload Around 30-40

Axis 6

Communications Profibus, can, devicenet, ethernet and serial channels (RS232

and RS485)

IO Capabilities PLC like capabilities to handle digital and analog IO

1.4 Objectives and Outline of the Book

The present book gives a detailed overview of Robotic Welding in the beginning of

the twenty-first century. The evolution of robotic welding is presented, showing to

the reader what were the biggest steps and developments observed in the last few

years. This is presented with the objective of establishing the current state-of-the-

art in terms of technologies, welding systems, software and sensors. The remaining

issues, i.e., the issues that remain open are stated clearly, in a way to motivate the

readers to follow the rest of the book which will make contributions to clarify most

of them and help to solve a few.

To do that, a chapter on “Welding Technology” is presented, describing the most

important welding techniques and their potential and requirements for automation

using robot manipulators. This chapter includes established results on robotic

welding processes, which can constitute a good source of information for readers

and also good source of examples.

Also, a revision with current research results on “Sensors for Welding Robots”

used on robotic welding is presented in the book. That includes sensors for seam

tracking, quality control and supervision. This chapter includes all system

requirements necessary to use those sensors and sensing techniques with actual

robot control systems. Hardware and software interfaces are also covered in detail.

A revision of available welding systems, including hardware and software,

clarifying their advantages, and drawbacks is also presented to give to the reader a

clear picture of the area. This is included in the chapter “Robotic Welding: System

Issues”.