Page 70 - Welding Robots Technology, System Issues, and Applications

P. 70

electrode force Welding Technology 55

weld nugget

R

1

R

current 2 R 3

source R

4

R

5

electrode electric temperature

resistance

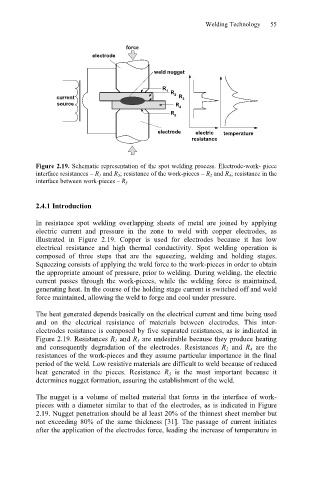

Figure 2.19. Schematic representation of the spot welding process. Electrode-work- piece

interface resistances – R 1 and R 5 ; resistance of the work-pieces – R 2 and R 4 ; resistance in the

interface between work-pieces – R 3

2.4.1 Introduction

In resistance spot welding overlapping sheets of metal are joined by applying

electric current and pressure in the zone to weld with copper electrodes, as

illustrated in Figure 2.19. Copper is used for electrodes because it has low

electrical resistance and high thermal conductivity. Spot welding operation is

composed of three steps that are the squeezing, welding and holding stages.

Squeezing consists of applying the weld force to the work-pieces in order to obtain

the appropriate amount of pressure, prior to welding. During welding, the electric

current passes through the work-pieces, while the welding force is maintained,

generating heat. In the course of the holding stage current is switched off and weld

force maintained, allowing the weld to forge and cool under pressure.

The heat generated depends basically on the electrical current and time being used

and on the electrical resistance of materials between electrodes. This inter-

electrodes resistance is composed by five separated resistances, as is indicated in

Figure 2.19. Resistances R 1 and R 5 are undesirable because they produce heating

and consequently degradation of the electrodes. Resistances R 2 and R 4 are the

resistances of the work-pieces and they assume particular importance in the final

period of the weld. Low resistive materials are difficult to weld because of reduced

heat generated in the pieces. Resistance R 3 is the most important because it

determines nugget formation, assuring the establishment of the weld.

The nugget is a volume of melted material that forms in the interface of work-

pieces with a diameter similar to that of the electrodes, as is indicated in Figure

2.19. Nugget penetration should be al least 20% of the thinnest sheet member but

not exceeding 80% of the same thickness [31]. The passage of current initiates

after the application of the electrodes force, leading the increase of temperature in