Page 110 - Well Control for Completions and Interventions

P. 110

102 Well Control for Completions and Interventions

3.3 TUBULAR CONNECTIONS

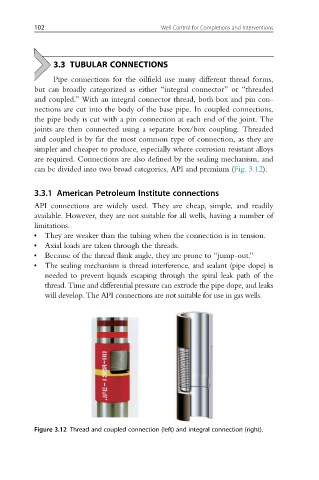

Pipe connections for the oilfield use many different thread forms,

but can broadly categorized as either “integral connector” or “threaded

and coupled.” With an integral connector thread, both box and pin con-

nections are cut into the body of the base pipe. In coupled connections,

the pipe body is cut with a pin connection at each end of the joint. The

joints are then connected using a separate box/box coupling. Threaded

and coupled is by far the most common type of connection, as they are

simpler and cheaper to produce, especially where corrosion resistant alloys

are required. Connections are also defined by the sealing mechanism, and

can be divided into two broad categories, API and premium (Fig. 3.12).

3.3.1 American Petroleum Institute connections

API connections are widely used. They are cheap, simple, and readily

available. However, they are not suitable for all wells, having a number of

limitations.

• They are weaker than the tubing when the connection is in tension.

• Axial loads are taken through the threads.

• Because of the thread flank angle, they are prone to “jump-out.”

• The sealing mechanism is thread interference, and sealant (pipe dope) is

needed to prevent liquids escaping through the spiral leak path of the

thread.Timeand differential pressurecanextrudethepipedope, andleaks

will develop. The API connections are not suitable for use in gas wells.

Figure 3.12 Thread and coupled connection (left) and integral connection (right).