Page 170 - Well Control for Completions and Interventions

P. 170

162 Well Control for Completions and Interventions

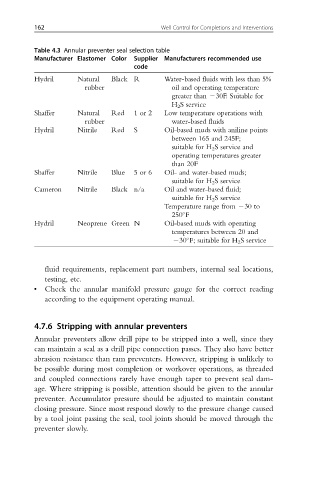

Table 4.3 Annular preventer seal selection table

Manufacturer Elastomer Color Supplier Manufacturers recommended use

code

Hydril Natural Black R Water-based fluids with less than 5%

rubber oil and operating temperature

greater than 230F. Suitable for

H 2 S service

Shaffer Natural Red 1 or 2 Low temperature operations with

rubber water-based fluids

Hydril Nitrile Red S Oil-based muds with aniline points

between 165 and 245F;

suitable for H 2 S service and

operating temperatures greater

than 20F

Shaffer Nitrile Blue 5 or 6 Oil- and water-based muds;

suitable for H 2 S service

Cameron Nitrile Black n/a Oil and water-based fluid;

suitable for H 2 S service

Temperature range from 230 to

250 F

Hydril Neoprene Green N Oil-based muds with operating

temperatures between 20 and

230 F; suitable for H 2 S service

fluid requirements, replacement part numbers, internal seal locations,

testing, etc.

• Check the annular manifold pressure gauge for the correct reading

according to the equipment operating manual.

4.7.6 Stripping with annular preventers

Annular preventers allow drill pipe to be stripped into a well, since they

can maintain a seal as a drill pipe connection passes. They also have better

abrasion resistance than ram preventers. However, stripping is unlikely to

be possible during most completion or workover operations, as threaded

and coupled connections rarely have enough taper to prevent seal dam-

age. Where stripping is possible, attention should be given to the annular

preventer. Accumulator pressure should be adjusted to maintain constant

closing pressure. Since most respond slowly to the pressure change caused

by a tool joint passing the seal, tool joints should be moved through the

preventer slowly.