Page 166 - Well Control for Completions and Interventions

P. 166

158 Well Control for Completions and Interventions

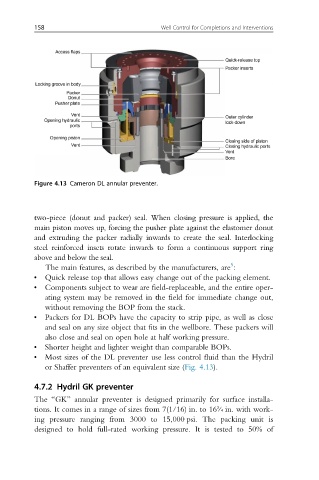

Figure 4.13 Cameron DL annular preventer.

two-piece (donut and packer) seal. When closing pressure is applied, the

main piston moves up, forcing the pusher plate against the elastomer donut

and extruding the packer radially inwards to create the seal. Interlocking

steel reinforced insets rotate inwards to form a continuous support ring

above and below the seal.

5

The main features, as described by the manufacturers, are :

• Quick release top that allows easy change out of the packing element.

• Components subject to wear are field-replaceable, and the entire oper-

ating system may be removed in the field for immediate change out,

without removing the BOP from the stack.

• Packers for DL BOPs have the capacity to strip pipe, as well as close

and seal on any size object that fits in the wellbore. These packers will

also close and seal on open hole at half working pressure.

• Shorter height and lighter weight than comparable BOPs.

• Most sizes of the DL preventer use less control fluid than the Hydril

or Shaffer preventers of an equivalent size (Fig. 4.13).

4.7.2 Hydril GK preventer

The “GK” annular preventer is designed primarily for surface installa-

3

tions. It comes in a range of sizes from 7(1/16) in. to 16/4 in. with work-

ing pressure ranging from 3000 to 15,000 psi. The packing unit is

designed to hold full-rated working pressure. It is tested to 50% of