Page 162 - Well Control for Completions and Interventions

P. 162

154 Well Control for Completions and Interventions

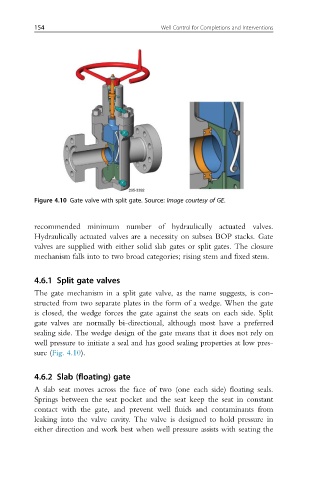

Figure 4.10 Gate valve with split gate. Source: Image courtesy of GE.

recommended minimum number of hydraulically actuated valves.

Hydraulically actuated valves are a necessity on subsea BOP stacks. Gate

valves are supplied with either solid slab gates or split gates. The closure

mechanism falls into to two broad categories; rising stem and fixed stem.

4.6.1 Split gate valves

The gate mechanism in a split gate valve, as the name suggests, is con-

structed from two separate plates in the form of a wedge. When the gate

is closed, the wedge forces the gate against the seats on each side. Split

gate valves are normally bi-directional, although most have a preferred

sealing side. The wedge design of the gate means that it does not rely on

well pressure to initiate a seal and has good sealing properties at low pres-

sure (Fig. 4.10).

4.6.2 Slab (floating) gate

A slab seat moves across the face of two (one each side) floating seals.

Springs between the seat pocket and the seat keep the seat in constant

contact with the gate, and prevent well fluids and contaminants from

leaking into the valve cavity. The valve is designed to hold pressure in

either direction and work best when well pressure assists with seating the