Page 158 - Well Control for Completions and Interventions

P. 158

150 Well Control for Completions and Interventions

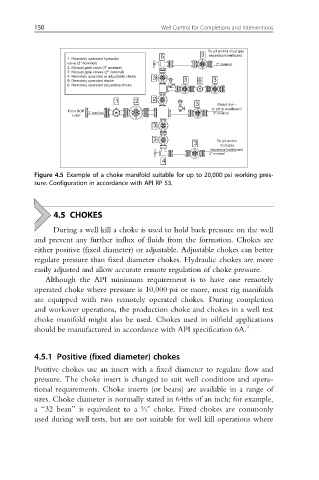

To pit and/or mud-gas

5 3 separator/overboard

1: Remotely operated hydraulic

valve (3” nominal) 2” nominal

2: Manual gate valve (3” nominal)

3: Manual gate valves (2” nominal)

4: Remotely operated or adjustable choke 3

5: Remotely operated choke 3 6 3

6: Remotely operated adjustable choke

1 2 2

3 Bleed line –

to pit or overboard

From BOP 3” nominal 2” nominal

outlet

3

3 To pit and/or

3 mud-gas

separator/overboard

2” nominal

4

Figure 4.5 Example of a choke manifold suitable for up to 20,000 psi working pres-

sure. Configuration in accordance with API RP 53.

4.5 CHOKES

During a well kill a choke is used to hold back pressure on the well

and prevent any further influx of fluids from the formation. Chokes are

either positive (fixed diameter) or adjustable. Adjustable chokes can better

regulate pressure than fixed diameter chokes. Hydraulic chokes are more

easily adjusted and allow accurate remote regulation of choke pressure.

Although the API minimum requirement is to have one remotely

operated choke where pressure is 10,000 psi or more, most rig manifolds

are equipped with two remotely operated chokes. During completion

and workover operations, the production choke and chokes in a well test

choke manifold might also be used. Chokes used in oilfield applications

4

should be manufactured in accordance with API specification 6A.

4.5.1 Positive (fixed diameter) chokes

Positive chokes use an insert with a fixed diameter to regulate flow and

pressure. The choke insert is changed to suit well conditions and opera-

tional requirements. Choke inserts (or beans) are available in a range of

sizes. Choke diameter is normally stated in 64ths of an inch; for example,

a “32 bean” is equivalent to a /2v choke. Fixed chokes are commonly

1

used during well tests, but are not suitable for well kill operations where