Page 263 - Well Control for Completions and Interventions

P. 263

Well Kill, Kick Detection, and Well Shut-In 257

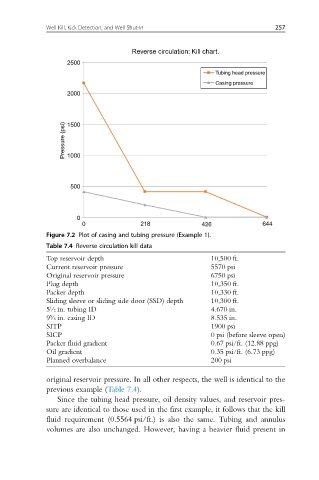

Reverse circulation: Kill chart.

2500

Tubing head pressure

Casing pressure

2000

Pressure (psi) 1500

1000

500

0

0 218 426 644

Figure 7.2 Plot of casing and tubing pressure (Example 1).

Table 7.4 Reverse circulation kill data

Top reservoir depth 10,500 ft.

Current reservoir pressure 5570 psi

Original reservoir pressure 6750 psi

Plug depth 10,350 ft.

Packer depth 10,330 ft.

Sliding sleeve or sliding side door (SSD) depth 10,300 ft.

1

5/2 in. tubing ID 4.670 in.

5

9/8 in. casing ID 8.535 in.

SITP 1900 psi

SICP 0 psi (before sleeve open)

Packer fluid gradient 0.67 psi/ft. (12.88 ppg)

Oil gradient 0.35 psi/ft. (6.73 ppg)

Planned overbalance 200 psi

original reservoir pressure. In all other respects, the well is identical to the

previous example (Table 7.4).

Since the tubing head pressure, oil density values, and reservoir pres-

sure are identical to those used in the first example, it follows that the kill

fluid requirement (0.5564 psi/ft.) is also the same. Tubing and annulus

volumes are also unchanged. However, having a heavier fluid present in