Page 270 - Well Control for Completions and Interventions

P. 270

264 Well Control for Completions and Interventions

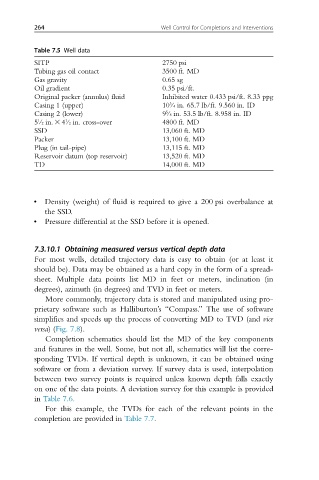

Table 7.5 Well data

SITP 2750 psi

Tubing gas oil contact 3500 ft. MD

Gas gravity 0.65 sg

Oil gradient 0.35 psi/ft.

Original packer (annulus) fluid Inhibited water 0.433 psi/ft. 8.33 ppg

3

Casing 1 (upper) 10/4 in. 65.7 lb/ft. 9.560 in. ID

5

Casing 2 (lower) 9/8 in. 53.5 lb/ft. 8.958 in. ID

1

5/2 in. 3 4/2 in. cross-over 4800 ft. MD

1

SSD 13,060 ft. MD

Packer 13,100 ft. MD

Plug (in tail-pipe) 13,115 ft. MD

Reservoir datum (top reservoir) 13,520 ft. MD

TD 14,000 ft. MD

• Density (weight) of fluid is required to give a 200 psi overbalance at

the SSD.

• Pressure differential at the SSD before it is opened.

7.3.10.1 Obtaining measured versus vertical depth data

For most wells, detailed trajectory data is easy to obtain (or at least it

should be). Data may be obtained as a hard copy in the form of a spread-

sheet. Multiple data points list MD in feet or meters, inclination (in

degrees), azimuth (in degrees) and TVD in feet or meters.

More commonly, trajectory data is stored and manipulated using pro-

prietary software such as Halliburton’s “Compass.” The use of software

simplifies and speeds up the process of converting MD to TVD (and vice

versa)(Fig. 7.8).

Completion schematics should list the MD of the key components

and features in the well. Some, but not all, schematics will list the corre-

sponding TVDs. If vertical depth is unknown, it can be obtained using

software or from a deviation survey. If survey data is used, interpolation

between two survey points is required unless known depth falls exactly

on one of the data points. A deviation survey for this example is provided

in Table 7.6.

For this example, the TVDs for each of the relevant points in the

completion are provided in Table 7.7.