Page 284 - Wind Energy Handbook

P. 284

258 DESIGN LOADS FOR HORIZONTAL-AXIS WIND TURBINES

NACELLE

Blade tip -

deflected position

Q

Blade tip -

undeflected position

Blade section

with maximum twist

β

P

δ 11

δ 12

Weak principal axis

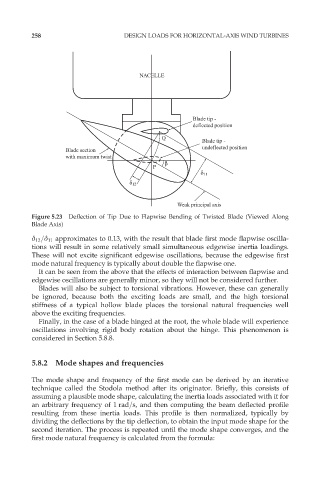

Figure 5.23 Deflection of Tip Due to Flapwise Bending of Twisted Blade (Viewed Along

Blade Axis)

ä 12 =ä 11 approximates to 0.13, with the result that blade first mode flapwise oscilla-

tions will result in some relatively small simultaneous edgewise inertia loadings.

These will not excite significant edgewise oscillations, because the edgewise first

mode natural frequency is typically about double the flapwise one.

It can be seen from the above that the effects of interaction between flapwise and

edgewise oscillations are generally minor, so they will not be considered further.

Blades will also be subject to torsional vibrations. However, these can generally

be ignored, because both the exciting loads are small, and the high torsional

stiffness of a typical hollow blade places the torsional natural frequencies well

above the exciting frequencies.

Finally, in the case of a blade hinged at the root, the whole blade will experience

oscillations involving rigid body rotation about the hinge. This phenomenon is

considered in Section 5.8.8.

5.8.2 Mode shapes and frequencies

The mode shape and frequency of the first mode can be derived by an iterative

technique called the Stodola method after its originator. Briefly, this consists of

assuming a plausible mode shape, calculating the inertia loads associated with it for

an arbitrary frequency of 1 rad=s, and then computing the beam deflected profile

resulting from these inertia loads. This profile is then normalized, typically by

dividing the deflections by the tip deflection, to obtain the input mode shape for the

second iteration. The process is repeated until the mode shape converges, and the

first mode natural frequency is calculated from the formula: