Page 118 - Mechanical Behavior of Materials

P. 118

Section 4.1 Introduction 119

(c)

(a) (b) (d)

(f)

(e) (g)

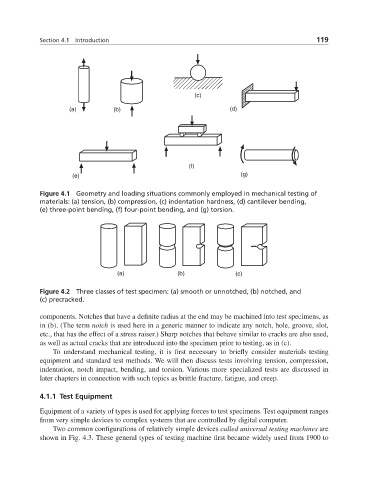

Figure 4.1 Geometry and loading situations commonly employed in mechanical testing of

materials: (a) tension, (b) compression, (c) indentation hardness, (d) cantilever bending,

(e) three-point bending, (f) four-point bending, and (g) torsion.

(a) (b) (c)

Figure 4.2 Three classes of test specimen: (a) smooth or unnotched, (b) notched, and

(c) precracked.

components. Notches that have a definite radius at the end may be machined into test specimens, as

in (b). (The term notch is used here in a generic manner to indicate any notch, hole, groove, slot,

etc., that has the effect of a stress raiser.) Sharp notches that behave similar to cracks are also used,

as well as actual cracks that are introduced into the specimen prior to testing, as in (c).

To understand mechanical testing, it is first necessary to briefly consider materials testing

equipment and standard test methods. We will then discuss tests involving tension, compression,

indentation, notch impact, bending, and torsion. Various more specialized tests are discussed in

later chapters in connection with such topics as brittle fracture, fatigue, and creep.

4.1.1 Test Equipment

Equipment of a variety of types is used for applying forces to test specimens. Test equipment ranges

from very simple devices to complex systems that are controlled by digital computer.

Two common configurations of relatively simple devices called universal testing machines are

shown in Fig. 4.3. These general types of testing machine first became widely used from 1900 to