Page 165 - Mechanical Behavior of Materials

P. 165

166 Chapter 4 Mechanical Testing: Tension Test and Other Basic Tests

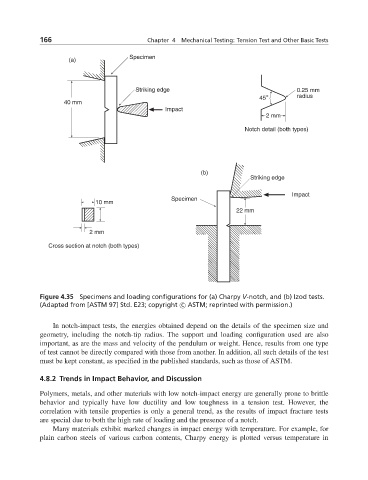

Specimen

(a)

Striking edge 0.25 mm

45 o radius

40 mm

Impact

2 mm

Notch detail (both types)

(b)

Striking edge

Impact

Specimen

10 mm

22 mm

2 mm

Cross section at notch (both types)

Figure 4.35 Specimens and loading configurations for (a) Charpy V-notch, and (b) Izod tests.

(Adapted from [ASTM 97] Std. E23; copyright c ASTM; reprinted with permission.)

In notch-impact tests, the energies obtained depend on the details of the specimen size and

geometry, including the notch-tip radius. The support and loading configuration used are also

important, as are the mass and velocity of the pendulum or weight. Hence, results from one type

of test cannot be directly compared with those from another. In addition, all such details of the test

must be kept constant, as specified in the published standards, such as those of ASTM.

4.8.2 Trends in Impact Behavior, and Discussion

Polymers, metals, and other materials with low notch-impact energy are generally prone to brittle

behavior and typically have low ductility and low toughness in a tension test. However, the

correlation with tensile properties is only a general trend, as the results of impact fracture tests

are special due to both the high rate of loading and the presence of a notch.

Many materials exhibit marked changes in impact energy with temperature. For example, for

plain carbon steels of various carbon contents, Charpy energy is plotted versus temperature in