Page 169 - Mechanical Behavior of Materials

P. 169

170 Chapter 4 Mechanical Testing: Tension Test and Other Basic Tests

P

P

t

2c

L L L

1 1

P/2 P/2 P/2 P/2

(a) (b)

v

(c)

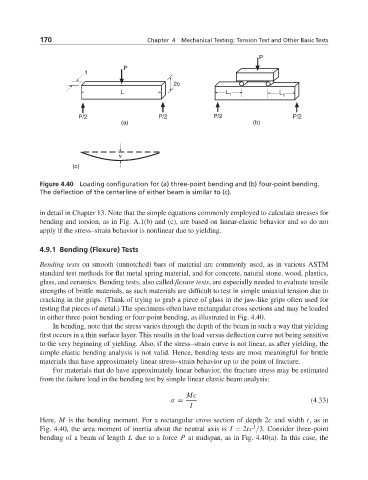

Figure 4.40 Loading configuration for (a) three-point bending and (b) four-point bending.

The deflection of the centerline of either beam is similar to (c).

in detail in Chapter 13. Note that the simple equations commonly employed to calculate stresses for

bending and torsion, as in Fig. A.1(b) and (c), are based on linear-elastic behavior and so do not

apply if the stress–strain behavior is nonlinear due to yielding.

4.9.1 Bending (Flexure) Tests

Bending tests on smooth (unnotched) bars of material are commonly used, as in various ASTM

standard test methods for flat metal spring material, and for concrete, natural stone, wood, plastics,

glass, and ceramics. Bending tests, also called flexure tests, are especially needed to evaluate tensile

strengths of brittle materials, as such materials are difficult to test in simple uniaxial tension due to

cracking in the grips. (Think of trying to grab a piece of glass in the jaw-like grips often used for

testing flat pieces of metal.) The specimens often have rectangular cross sections and may be loaded

in either three-point bending or four-point bending, as illustrated in Fig. 4.40.

In bending, note that the stress varies through the depth of the beam in such a way that yielding

first occurs in a thin surface layer. This results in the load versus deflection curve not being sensitive

to the very beginning of yielding. Also, if the stress–strain curve is not linear, as after yielding, the

simple elastic bending analysis is not valid. Hence, bending tests are most meaningful for brittle

materials that have approximately linear stress–strain behavior up to the point of fracture.

For materials that do have approximately linear behavior, the fracture stress may be estimated

from the failure load in the bending test by simple linear elastic beam analysis:

Mc

σ = (4.33)

I

Here, M is the bending moment. For a rectangular cross section of depth 2c and width t,asin

3

Fig. 4.40, the area moment of inertia about the neutral axis is I = 2tc /3. Consider three-point

bending of a beam of length L due to a force P at midspan, as in Fig. 4.40(a). In this case, the