Page 213 - Mechanical Behavior of Materials

P. 213

214 Chapter 5 Stress–Strain Relationships and Behavior

5.4 ANISOTROPIC MATERIALS

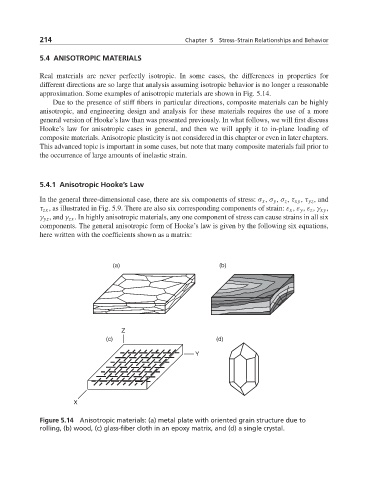

Real materials are never perfectly isotropic. In some cases, the differences in properties for

different directions are so large that analysis assuming isotropic behavior is no longer a reasonable

approximation. Some examples of anisotropic materials are shown in Fig. 5.14.

Due to the presence of stiff fibers in particular directions, composite materials can be highly

anisotropic, and engineering design and analysis for these materials requires the use of a more

general version of Hooke’s law than was presented previously. In what follows, we will first discuss

Hooke’s law for anisotropic cases in general, and then we will apply it to in-plane loading of

composite materials. Anisotropic plasticity is not considered in this chapter or even in later chapters.

This advanced topic is important in some cases, but note that many composite materials fail prior to

the occurrence of large amounts of inelastic strain.

5.4.1 Anisotropic Hooke’s Law

In the general three-dimensional case, there are six components of stress: σ x , σ y , σ z , τ xy , τ yz , and

τ zx , as illustrated in Fig. 5.9. There are also six corresponding components of strain: ε x , ε y , ε z , γ xy ,

γ yz , and γ zx . In highly anisotropic materials, any one component of stress can cause strains in all six

components. The general anisotropic form of Hooke’s law is given by the following six equations,

here written with the coefficients shown as a matrix:

(a) (b)

Z

(c) (d)

Y

X

Figure 5.14 Anisotropic materials: (a) metal plate with oriented grain structure due to

rolling, (b) wood, (c) glass-fiber cloth in an epoxy matrix, and (d) a single crystal.