Page 369 - Mechanical Behavior of Materials

P. 369

370 Chapter 8 Fracture of Cracked Members

σ = S

t

6

5

4

a 2 3 t

1

(a) 2c

σ or σ

x t

(cylinder

2c or sphere)

t

(b)

2c ≥ 2t

c

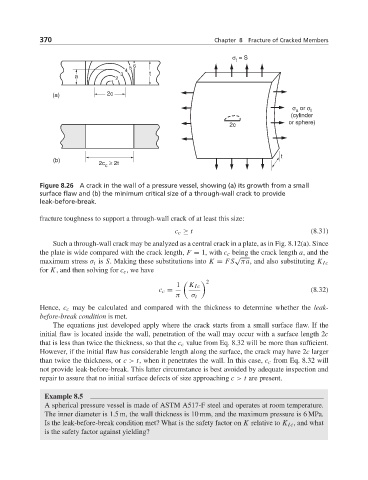

Figure 8.26 A crack in the wall of a pressure vessel, showing (a) its growth from a small

surface flaw and (b) the minimum critical size of a through-wall crack to provide

leak-before-break.

fracture toughness to support a through-wall crack of at least this size:

c c ≥ t (8.31)

Such a through-wall crack may be analyzed as a central crack in a plate, as in Fig. 8.12(a). Since

the plate is wide compared with the crack length, F = 1, with c c being the crack length a, and the

√

maximum stress σ t is S. Making these substitutions into K = FS πa, and also substituting K Ic

for K, and then solving for c c ,wehave

2

1 K Ic

c c = (8.32)

π σ t

Hence, c c may be calculated and compared with the thickness to determine whether the leak-

before-break condition is met.

The equations just developed apply where the crack starts from a small surface flaw. If the

initial flaw is located inside the wall, penetration of the wall may occur with a surface length 2c

that is less than twice the thickness, so that the c c value from Eq. 8.32 will be more than sufficient.

However, if the initial flaw has considerable length along the surface, the crack may have 2c larger

than twice the thickness, or c > t, when it penetrates the wall. In this case, c c from Eq. 8.32 will

not provide leak-before-break. This latter circumstance is best avoided by adequate inspection and

repair to assure that no initial surface defects of size approaching c > t are present.

Example 8.5

A spherical pressure vessel is made of ASTM A517-F steel and operates at room temperature.

The inner diameter is 1.5 m, the wall thickness is 10 mm, and the maximum pressure is 6 MPa.

Is the leak-before-break condition met? What is the safety factor on K relative to K Ic , and what

is the safety factor against yielding?