Page 40 - Mechanical Behavior of Materials

P. 40

Section 2.1 Introduction 41

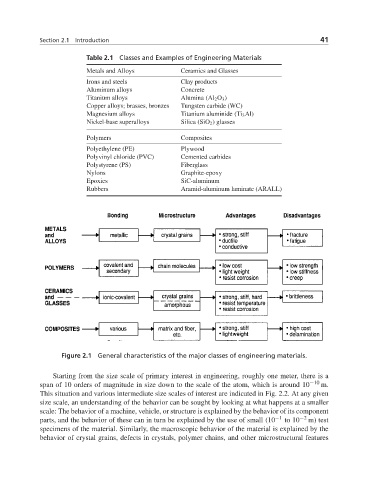

Table 2.1 Classes and Examples of Engineering Materials

Metals and Alloys Ceramics and Glasses

Irons and steels Clay products

Aluminum alloys Concrete

Titanium alloys Alumina (Al 2 O 3 )

Copper alloys; brasses, bronzes Tungsten carbide (WC)

Magnesium alloys Titanium aluminide (Ti 3 Al)

Nickel-base superalloys Silica (SiO 2 ) glasses

Polymers Composites

Polyethylene (PE) Plywood

Polyvinyl chloride (PVC) Cemented carbides

Polystyrene (PS) Fiberglass

Nylons Graphite-epoxy

Epoxies SiC-aluminum

Rubbers Aramid-aluminum laminate (ARALL)

Figure 2.1 General characteristics of the major classes of engineering materials.

Starting from the size scale of primary interest in engineering, roughly one meter, there is a

span of 10 orders of magnitude in size down to the scale of the atom, which is around 10 −10 m.

This situation and various intermediate size scales of interest are indicated in Fig. 2.2. At any given

size scale, an understanding of the behavior can be sought by looking at what happens at a smaller

scale: The behavior of a machine, vehicle, or structure is explained by the behavior of its component

parts, and the behavior of these can in turn be explained by the use of small (10 −1 to 10 −2 m) test

specimens of the material. Similarly, the macroscopic behavior of the material is explained by the

behavior of crystal grains, defects in crystals, polymer chains, and other microstructural features